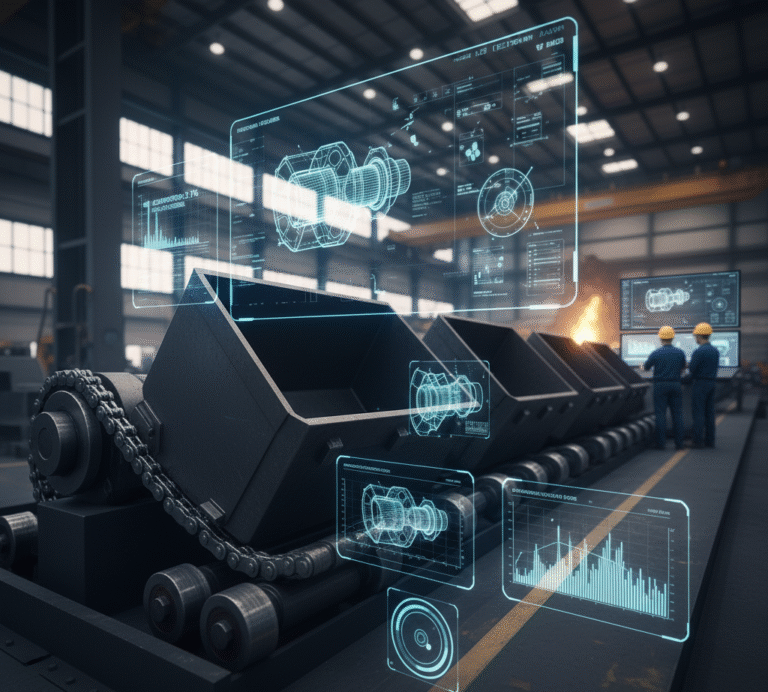

Technical Highlights: Intelligent Monitoring & Diagnostics

Our AI-integrated sensor suite provides comprehensive, real-time monitoring of both machinery health and operating conditions. Built for tough industrial environments, every sensor module is ruggedized (e.g. weatherproof to IP69 and designed for -20°C to +80°C operation) to withstand high dust, heat, and vibration.

Below are key monitoring capabilities of the Constromech system, each delivering early warning of potential problems:

Motor Performance (Current & Torque):

High-precision current sensors and torque monitoring algorithms track motor load in real time. Spikes or deviations in motor current draw are analysed to detect jams, overloads, or inefficiencies in the drive system. This helps catch issues like impending drive failures or material blockages early – for instance, our AI-based current signature analysis can identify abnormal load changes or belt slip before an operator notices. By continuously comparing torque trends against normal profiles, the system ensures motors and gearboxes operate within safe limits, preventing excessive strain and energy waste.

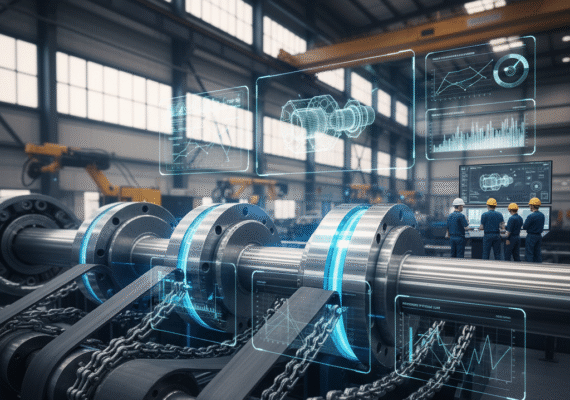

Shaft Alignment & Tensioning:

The system monitors the mechanical alignment of shafts and couplings through vibration pattern analysis, spotting misalignment or imbalance that can lead to premature wear. In addition, dedicated tension sensors keep track of belt and chain tension/elongation. A chain/belt elongation module measures take-up displacement or stretch – effectively acting as an “over-travel” switch that alerts when a chain has elongated beyond tolerance. This indicates when re-tensioning or part replacement is due. By catching shaft misalignment and chain stretch conditions early, the system prevents catastrophic failures like coupling breaks or chain snaps. It also provides a basis for predicting remaining fatigue life of these components.

Bucket/Pan Fill, Material Flow & Spillage:

Our solution also keeps an eye on the material itself – ensuring your equipment is moving product efficiently without blockages or losses. Level sensors in the pan travel structure or bucket elevator boot detect whether buckets/pans are filling properly, and ultrasonic or laser-based flow sensors gauge the material throughput on conveyors/elevators. The AI can thus discern irregular flow or empty buckets, signalling upstream feed issues before they halt production.

Blocked chute detectors and plugged condition switches are integrated to sense any material backup in spouts or transfer points. Additionally, spillage sensors (such as pressure plates or tilt switches along conveyor edges) trigger an alert or shutdown if excess material is detected outside the system. This multi-point flow monitoring not only helps maintain consistent output but also minimizes waste and cleanup – preventing scenarios where mis-tracking belts/chains spill material or chutes overflow unnoticed.