Submerged Overhanging Idler (SOI) / Inner Guide Wheel For Submerged Scraper Chain Conveyors in Thermal Power Plants

CMECH offers precision-engineered Submerged Overhanging Idler Wheels — also referred to as Inner Guide Wheels — specifically developed for bottom ash handling systems in submerged scraper chain conveyors (SSCCs).

These wheels are a critical part of ash removal systems, operating in submerged and high-abrasion environments at the tail end of thermal power plant boilers.

Typical Application

- Submerged Scraper Conveyors (SSCCs)

- Bottom ash dewatering and discharge systems

- Wet chain conveyors in boiler ash zones

- Reversible and uni-directional bottom ash conveyors

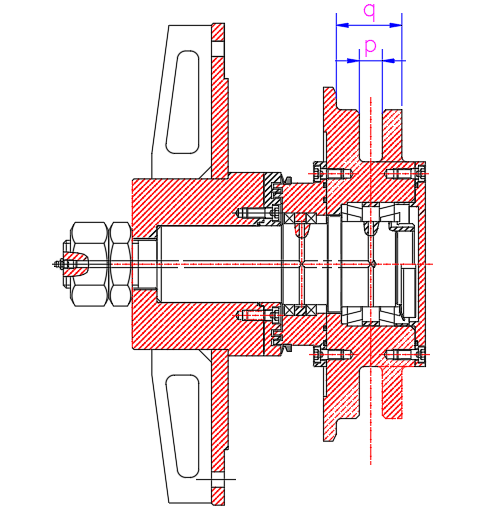

Design & Construction

Each wheel is designed to operate in submerged or semi-submerged conditions with continuous exposure to:

- Abrasive bottom ash

- Water/moisture cycles

- Thermal gradients and high mechanical loads

CMECH wheels are provided with:

- Integrated cantilevered shaft mountings for direct frame fitment

- Flanged outer ring design to guide the scraper chain movement within the trough

- Stress-relieved cast or forged alloy steel bodies, for long-life performance in corrosive-slurry environments

Size Range & Variants

- Available in PCD sizes from 400 mm to 650 mm

- Shaft diameters from 19 mm to 42 mm, depending on load

- Idler thickness and spacing as per OEM standards (Ashtech, Macawber, Clyde Bergemann, etc.)

- Lubrication options: Sealed-for-life or grease-packed as per site demand

Why Choose CMECH Submerged Idlers?

- Precision Fit for submerged chain tracks — avoids misalignment

- Hardened bearing surface zones for increased wear resistance

- Custom-built with flange & shaft assembly for direct integration

- No jamming under thermal expansion due to guided axial tolerance

- Field-tested in NTPC, Tata Power, JSW, and other thermal utility setups

Optional Enhancements:

- 316L stainless steel variants for higher corrosion resistance

- Surface coatings for enhanced ash-slurry performance

- Non-metallic wheel options for isolated applications

Let CMECH Support Your Bottom Ash Systems

Improve conveyor uptime, reduce idler jamming, and extend overhaul cycles.Ask for drawings, custom configurations, or drop-in replacements

Submerged Overhanging Idler (SOI)

| PCD | d/mm | p | q |

| 400 | 19 | 24 | 83 |

| 400 | 22 | 27 | 92 |

| 400 | 26 | 32 | 107 |

| 566 | 30 | 36 | 113 |

| 560 | 34 | 42 | 127 |

| 566 | 36 | 42 | 136 |

| 650 | 42 | 50 | 155 |

| 511 | 30 | 36 | 113 |