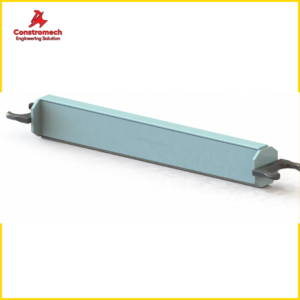

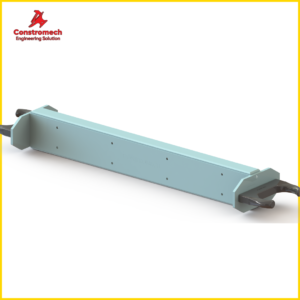

Scrapper Bar

Engineered for Extreme Conditions. Fabricated for Long Life.

Constromech offers robust, custom-fabricated scraper bars designed for heavy-duty bottom ash conveyor systems in thermal power plants. Our scraper bars combine precisely engineered fabrication, advanced cladding, and metallurgy-aligned forging—ensuring superior wear resistance and seamless performance under the harshest ash handling conditions.

Product Construction:

-

- Structure: Scrapers are fabricated using heavy-duty structural channels, angles, or rectangular pipes, chosen for high mechanical load capacity and corrosion resistance asper their yield strength and higher fatigue points.

-

- Scraping Surface:

-

- Cladded with welded-on wear-resistant hard plates, typically in the 440–500 BHN range, tailored to the ash abrasiveness and plant requirement.

-

- Hard-plating ensures maximum lifespan even under high-temperature and abrasive slurry environments.

-

- Scraping Surface:

-

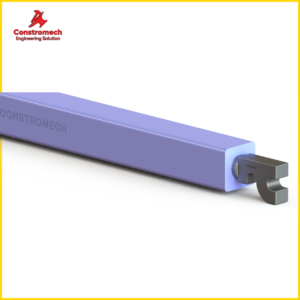

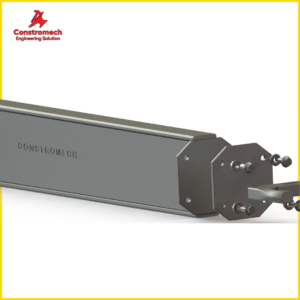

- End Connectors:

-

- Manufactured from forged alloy steel to match the hardness, tensile and fatigue properties of the paired round link chains.

-

- Heat-treated up to 55 HRc, chemically matched to prevent interface erosion and ensure mechanical integrity.

-

- End Connectors:

Key Advantages:

| Feature | Benefit |

| Fabricated Modular Design | Easy field replacement and adaptable to various conveyor widths |

| Welded Hard Cladding (440–500 BHN) | Exceptional abrasion resistance in high-wear bottom ash environments |

| Forged & Heat-Treated Connectors (up to 55 HRc) | Matched mechanical performance with round link chains |

| Custom Lengths & Profiles | Precision-fitted to trough design and material characteristics |

| Compatibility | Works seamlessly with standard submerged and dry bottom ash conveyor systems |

Ideal for

-

- Submerged Chain Conveyors (SCC)

-

- Dry Bottom Ash Handling Systems

-

- Power Plants up to Ultra Supercritical Grade

Backed by decades of field-tested experience, our scraper bars are in active deployment across leading Indian and international thermal power plants.

Let’s Talk Performance

Looking to reduce scraper wear or downtime in your ash handling systems? Contact us today to design your next-generation scraper bar solution—tailored to your exact wear profile and ash load conditions.

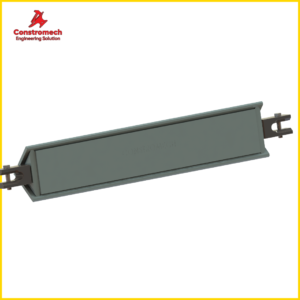

Fabricated Pans for Dry Ash Conveyors

At Constromech our fabricated pans are engineered specifically for dry bottom ash handling systems, delivering outstanding durability and performance in thermal power plants that rely on round-link chain conveyors.

Product Highlights

Heavy-Duty Fabrication

-

- Crafted from structural channels, angles, or rectangular steel pipes for top-tier structural integrity.

-

- Designed to withstand thermal shock from red-hot ash and large slag lumps.

Integrated Wear Protection

-

- Welded-on hard plates rated 440–500 BHN across the pan bottom and sides.

-

- Customizable hardness grades for specific plant operating conditions ensure minimal wear.

Round-Link Chain Compatibility

Built-in forged alloy steel connectors are heat-treated to ≈55 HRc, chemically and mechanically matched for seamless integration with your chain conveyors.

Modular & Service-Friendly

-

- Pans are bolt-together modular units—fast and easy swap-out during maintenance, reducing downtime.

-

- Smooth interiors reduce material hang-up and eliminate ash retention zones.

Key Benefits

| Feature | Benefit |

| Precision fabrication & weld quality | Enhanced structural strength; handles heavy ash loads and impacts |

| Wear-resistant hard cladding | Maintains long service life under abrasive conditions |

| Compatible connectors | Ensures secure fit with round-link chains, prevents fatigue |

| Service modularity | Enables rapid field assembly and maintenance |

| Adapted for dry conveyor cooling | Designed for dry ash in forced draft air-cooled environment |

Ideal Applications

-

- Dry bottom ash systems in thermal power plants

-

- Round-link chain conveyors using air-cooling

-

- Retrofit and new-build systems aiming to eliminate wet ash handling

Why Choose Constromech?

With deep expertise in bottom ash systems, we engineer pans that exceed the rigorous specifications. Our deliverables include:

-

- Customized pan sizes, wall thicknesses and wear plate configurations

-

- One to One replacement with OEM fitment

-

- Heat-treated connectors compatible with your chain assemblies

Full QC, material traceability, fabrication documentation, and onsite support

Ready for Performance & Reliability?

Fuel your pan requirements with Constromech engineering-grade design and fabrication. Contact us to match pan dimensions, material grades, connector specifications, and deliverables for maximum uptime.