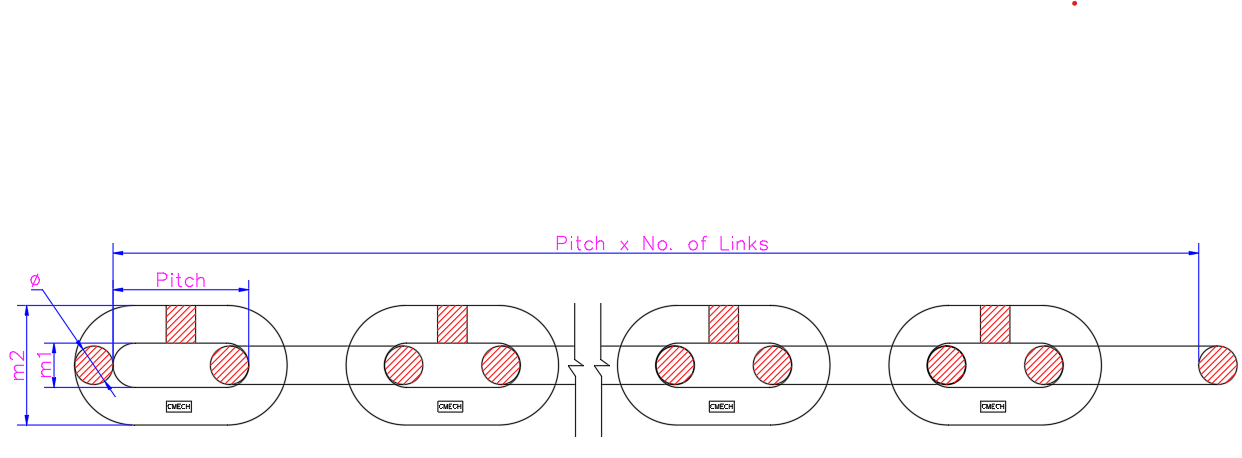

ROUND LINK CHAIN

Precision-engineered round link chains specifically designed for bucket elevators & chain conveyor operating in abrasive, high-load, and high-temperature environments typical of cement, mining, and power industries.

Built to DIN 764, DIN 766, and customer-specific configurations, our case-hardened chains offer exceptional mechanical performance, longevity, and reliability in demanding vertical conveying applications.

Technical Highlights & Construction Features

| Feature | Technical Detail |

| Chain Profile | Fully round cross-section forged from fine-grain alloy steel; ensures uniform load transfer and eliminates sharp corners that cause stress risers |

| Link Welding | Precision flash butt-welded and 100% crack-tested; each weld is proof-loaded and normalized to relieve residual stress |

| Heat Treatment | Core hardened and surface tempered (carburized or quenched & tempered); typical hardness range: 38–45 HRC for high wear resistance |

| Pitch Accuracy | Tight pitch tolerances (±0.2 mm) for smooth meshing with drive and idler sprockets; minimizes chain jump and uneven tensioning |

| Elongation Control | Controlled pre-stretching during manufacturing limits initial wear-related elongation in service |

| Proof Load & Breaking Load | Every batch proof-tested to 2× working load; breaking strength up to 3.5× rated load depending on chain size and grade |

Application Advantages in Bucket Elevators & chain conveyor

- True round profile ensures continuous contact with sprockets and reduces point loading

- Shock-resistant design handles impulse loads from heavy buckets and abrupt starts

- Low wear rate extends service intervals and reduces unplanned shutdowns

- Easy integration with DIN-compliant sprockets, shackles, and buckets

- Self-cleaning geometry minimizes buildup of fine or sticky materials

- Suitable for conveying hot, coarse, or highly abrasive materials such as clinker, coal, slag, limestone, and raw meal

Why Choose Constromech Chains?

Constromech is not just a supplier — we’re your engineering partner in elevating performance:

- Custom Solutions

- Tailor-made chains for non-standard pitches, high-lift elevators, or corrosive atmospheres

- Available in grades up to G100 and boron-alloy steels for superior fatigue strength

- OEM Compatibility

- Full backward compatibility with existing OEM or similar installations

- Chains optimized to match your drive sprocket geometry, bucket pitch, and shackle design

- In-House Quality Control

- All chains undergo NDT, load testing, hardness verification, and dimensional inspection

- Delivered with material certificates, QA reports, and traceability records

- Inventory & Turnaround

- Standard DIN sizes always in stock (10×28 up to 38×144 mm)

- Custom chains delivered within 2–4 weeks including heat treatment and proof testing

- End-to-End Support

- Assistance in chain selection, drive redesign, wear analysis, and service life prediction

- Available with welded attachments, pin-type bucket connectors, or adapter links

Industries Served

- Cement & Clinker Plants

- Thermal Power Stations

- Fertilizer & Chemical Plants

- Steel & Foundry Units

- Mining & Quarry Operations

Let Constromech engineer your next upgrade.

Whether you’re modernizing a 60-meter clinker elevator or replacing worn-out chains in a fly-ash elevator, we provide precision-built chains that deliver maximum uptime, optimal wear life, and seamless integration into your material handling system.

Tailor-made sizes as per client specifications and drawings are available

| Chain Size Ø x Pitch (mm) | Inside Width (m1) mm | Outside Width (m2) mm | DIN Chain |

| 10×28 | 12 | 36 | 766 |

| 10×35 | 14 | 36 | 764 |

| 13×45 | 18 | 47 | 764 |

| 14×50 | 16.3 | 47 | ND |

| 16×45 | 19.2 | 58 | 766 |

| 16×56 | 22 | 58 | 764 |

| 18×50 | 21.6 | 65 | 766 |

| 18×63 | 24 | 65 | 764 |

| 19×75 | 22 | 63 | ND |

| 20×56 | 24 | 72 | 766 |

| 20×70 | 27 | 72 | 764 |

| 22×86 | 26 | 74 | ND |

| 23×64 | 27.6 | 83 | 766 |

| 23×80 | 31.6 | 83 | 764 |

| 26×73 | 31.2 | 94 | 766 |

| 26×91 | 35 | 94 | 766 |

Table – Dimensions and qualities

| Chain Size Ø x Pitch (mm) | Inside Width (m1) mm | Outside Width (m2) mm | DIN Chain |

| 26×100 | 31 | 87 | ND |

| 28×78 | 33.6 | 101 | 766 |

| 28×98 | 36 | 101 | 764 |

| 30×84 | 36 | 108 | 766 |

| 30×105 | 39 | 108 | 764 |

| 30×120 | 36 | 102 | ND |

| 33×92 | 43 | 119 | 766 |

| 33×115 | 43 | 119 | 764 |

| 34×136 | 39 | 113 | ND |

| 36×101 | 43.2 | 130 | 766 |

| 36×126 | 47 | 130 | 764 |

| 38×144 | 44 | 127 | ND |

| 39×109 | 51 | 140 | 766 |

| 39×136 | 51 | 140 | 764 |

| 42×118 | 50 | 151 | 766 |

| 42×147 | 55 | 151 | 764 |