Key Product Categories

Constromech Solutions specializes in delivering customized solutions for Round Link Chain Elevators, offering a comprehensive range of essential components to optimize the performance of your system. Our expertise covers key elements such as Chain, Shaft Assembly, Attachments, Buckets, and Boot Bearing.

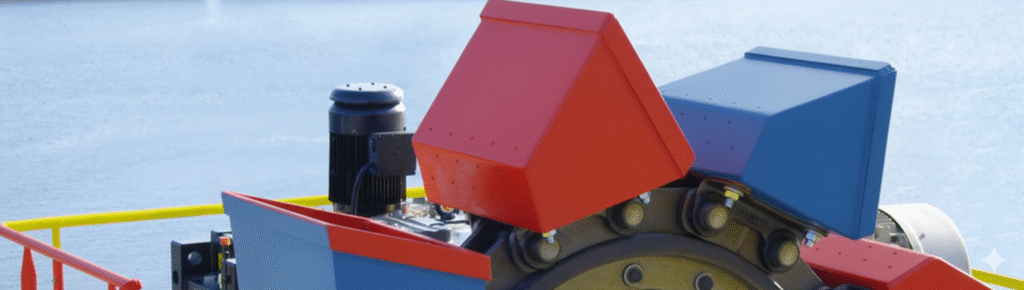

Constromech excels in providing tailored solutions for Round Link Chain Conveyors, offering a comprehensive array of essential components to optimize the efficiency of your system. Our expertise covers key elements such as Chain, Shaft Assembly, Attachments, Scraper Bar, Guide Wheel, Tensioning Arrangement, Submerged Overhanging Idler, and Tension Wheel.

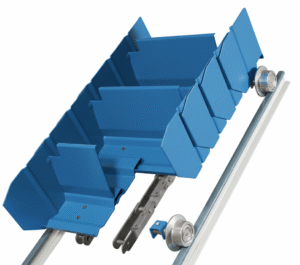

Constromech specializes in delivering tailored solutions for Pin Bush type Plate Link Chain Elevators, providing a comprehensive array of essential components to optimize the functionality of your system. Our expertise encompasses critical elements such as Chain, Head and Tail Rim Sprocket assembly, Buckets, Tensioning arrangement and Boot Bearing.

Constromech Solutions specializes in delivering tailored solutions for Deep Pan Conveyor Chain, providing a comprehensive array of essential components to optimize the efficiency of your system. Our expertise covers key elements such as Chain, Shaft Assembly, and Pan.

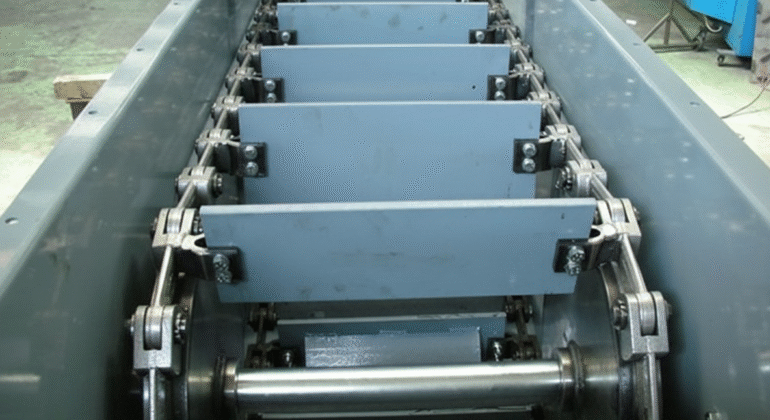

Constromech Solutions specializes in providing tailored solutions for Drag Chain Conveyors, offering a comprehensive array of essential components to optimize the efficiency of your system. In the context of a Drag Chain Conveyor, one of the key components is the Chain Sprocket Assembly.

Constromech Solutions excels in delivering tailored solutions for Belt Bucket Elevators. Our specialized offerings include essential components such as belts, head and tail pulleys, boot bearings, and buckets. We are committed to providing you with a meticulously coordinated set of parts that cater specifically to the unique requirements of belt bucket elevators

Stacker & Reclaimer chains are designed for continuous operation in bulk material yards where abrasive materials like limestone, coal, or clinker are handled. These chains are engineered for strength, stability, and minimal wear — essential for bridge-type reclaimers and stacker systems in cement and power plants.

Apron feeder chains are designed to move bulk materials with high impact, high abrasiveness, or large size — especially in mining, steel, cement, and power applications. Built with forged links and wear-resistant pans, these chains support slow-speed, heavy-load conveying in surge hoppers, crushers, and kilns.

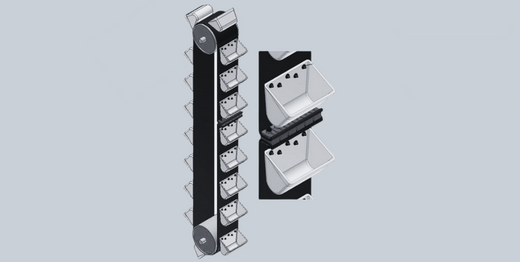

Flow conveyor chains are tailored for horizontal or low-angle conveying of powdered and granular materials — especially in cement kilns, fly ash systems, and additive dosing lines. These chains provide controlled flow with reduced wear and noise.

Why Choose CMECH?

✅ OEM Compatibility

✅ Tailor-Made Engineering

✅ Superior Surface Treatment & Heat Treatment

✅ On-Site Technical Support & Inspection

✅ Short Lead Times, High Precision

From the smallest component to the most complex conveying system, CMECH stands as a trusted partner for robust, reliable, and cost-effective solutions. Explore our detailed product offerings or get in touch to discuss how we can support your operations.