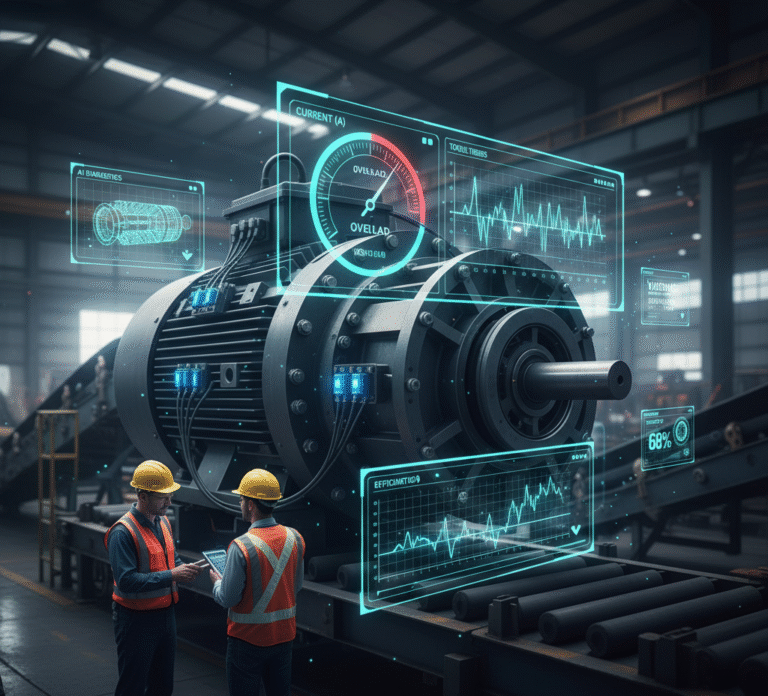

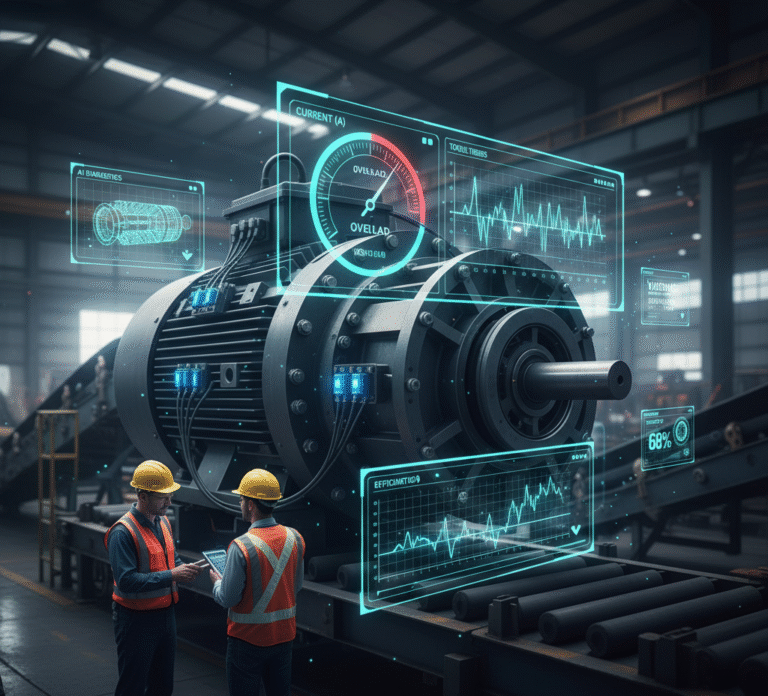

Intelligent Analytics & Interfaces

At the heart of the Constromech’s solutions is an AI-driven diagnostic engine that turns raw sensor data into actionable insights.

Unlike conventional alarm systems, which only react when a value crosses a setpoint, our predictive analytics learn the normal signature of each machine and detect subtle shifts that indicate emerging issues.

The algorithms incorporate deep domain knowledge (equipment design parameters and failure modes) plus data from many operating hours, allowing the system to recognize patterns that precede failures. In effect, the longer and wider the system is deployed, the smarter it becomes – each installation contributes to a growing knowledge base, improving anomaly detection accuracy across all units.

The diagnostic module automatically assesses the severity of any deviation and assigns alerts (warning vs alarm) with context.

Example

Tt might correlate a slight motor current increase with a specific vibration frequency rise and correctly pinpoint “early-stage coupling misalignment” rather than just issuing generic alarms.

User-friendly interfaces then bring these insights to your team: a unified web dashboard and mobile app display live data and trends for each asset, and can highlight KPIs like belt speed, load, temperature, etc., in real time.

When an issue is detected, the system pushes out instant notifications via email/SMS with clear descriptions of the fault. Maintenance staff can thus respond promptly with the right tools and parts. The platform also supports integration to plant control systems – for instance, it can feed alarm signals to a central PLC/SCADA if required for automatic machine shutdown or centralized logging.

Crucially, all this comes with minimal infrastructure hassle: the Constromech kit is wireless and plug-and-play, requiring no extensive cabling or PLC programming to get started. This means it’s equally suited to retrofits on legacy equipment as well as new installations. In sum, the intelligent interface ensures you not only gather a wealth of sensor data, but also benefit from AI-driven diagnoses, convenient monitoring tools, and flexible integration – turning raw data into a preventative maintenance action plan.

How does Constromech’s solution compare?

It goes far beyond traditional conveyor “hazard monitoring” systems that typically only watch a handful of points like speed or temperature.

By covering the full spectrum of operational and safety parameters in one package, our platform provides a level of situational awareness unmatched by piecemeal sensors. Moreover, the inclusion of machine learning for anomaly detection and life prediction sets it apart from threshold-based systems. Constromech’s diagnostics can tell you how long before a belt needs replacement, not just that it’s hot or misaligned right now – a fundamentally more useful approach to asset management.

The system is also inherently scalable and adaptable: you can outfit one conveyor or an entire plant and even add new sensor modules over time (for example, add air quality monitoring if regulations demand) without a complete overhaul. Because it’s an independent platform (wireless IoT architecture), deployment is quick and non-intrusive – there are no lengthy downtimes for installation or complex PLC integrations needed. This flexibility means our solution can be standardized across different machine types and brands, creating a unified monitoring ecosystem.

In short, Constromech’s AI-powered offering achieves broader coverage, deeper diagnostics, and easier scalability than conventional monitoring systems, futureproofing your operations as Industry 4.0 evolves.