Deep Pan Conveyor Chains

Technical Highlights & Construction Features

| Feature | Technical Detail |

| Chain Design | Drop-forged/Plate symmetrical links for bidirectional use; optimized for lateral strength |

| Material | Alloy steel with fine-grain structure for fatigue and impact resistance |

| Heat Treatment | Carburized or quenched & tempered; case-hardened to 45–55 HRC |

| Pin & Bush Assembly | Hardened pins and precision-machined bushings minimize elongation |

| Pitch Accuracy | Tight pitch tolerances (±0.25 mm) ensure smooth sprocket engagement |

| Lubrication Grooves | Optional oiling paths to enhance lifespan in hot zones |

| Proof Load Testing | Each chain batch proof-tested to 2× working load; destructive testing on request |

Application Advantages of Deep Pan Conveyors

Drop-forged /Plate link shape improves load distribution across conveyor pans.

Rugged construction resists impact from large clinker or slag chunks.

Hardened pin design reduces wear in abrasive environments.

Custom-fit to pans and side profiles for zero interference and low noise.

High-temperature resistance: suitable up to 350°C continuous operation.

Works seamlessly with Constromech or OEM sprockets, shafts, and pan attachments.

Why Choose Constromech Conveyor Chains?

Custom-Built Solutions

- Configured to suit pan width, pitch, and material type

- Available with split-link pins, wear plates, or guiding attachments

OEM Compatibility

- 100% retrofit with existing deep pan conveyors from European and Indian OEMs

- Pitch-matched to existing pans and drive sprockets

In-House Quality Assurance

- Full traceability of steel batches and treatments

- Each chain tested, serialized, and documented with QA report

Inventory & Turnaround

- Stocked standard models: CMECH-DPC125 to DPC400

- Custom chains delivered in 10–12 working days with optional heat treatment

Service Support

- Assistance with chain selection, wear analysis, and conveyor upgrades

- Optional full chain–sprocket–pan integration kits

Industries Served

Cement Plants (Kiln Feed, Clinker Coolers)

Thermal Power Stations (Ash Conveyors)

Steel & Foundry Units

Aggregate and Mining Operations

Fertilizer Bulk Handling Systems

Whether you’re planning a new conveyor line or replacing worn chains in an existing system, Constromech deep pan conveyor chains are precision-built to last — with quick lead times, engineering support, and backward compatibility for peace of mind.

Contact us today for a quote or design assistance.

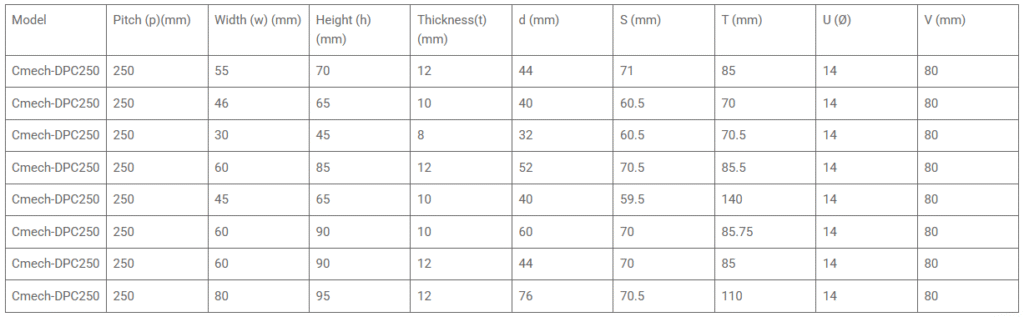

Deep Pan Conveyor table