Chain Wheels for Chain Conveyors

Precision-Engineered for Cement, Steel, and Power Plants

At CONSTROMECH, we manufacture high-performance chain wheels for heavy-duty chain conveyors used in cement kilns, clinker transport, steel scrap feeders, ash handling, and raw meal systems.

Our chain wheels are engineered for long service life, optimized load distribution, and minimal wear—tailored to the rigorous conditions of bulk material handling systems in continuous operation.

Applications:

- Cement Plants: kiln feed conveyors, clinker pan conveyors, bucket elevators

- Steel Plants: slag and scrap conveyors, billet cooling systems

- Power Plants: bottom ash drag conveyors, biomass intake chains

Technical Highlights

| Feature | Specification |

| Pitch Circle Diameters (PCD) | Ranging from 135 mm to 847 mm |

| DIN / Non-DIN Options | Compatible with DIN 764, 766, or customized for OEM fit |

| Steel Grades | Cast Steel (GS52), Forged Alloy Steel (EN8, EN19) |

| Heat Treatment | Induction-hardened chain contact areas up to 55 HRC |

| Tooth Profiles | Available in machined single, double, or triple row profiles |

| Mounting | Keyed bore, taper lock, or custom flange-mounted design |

Why CMECH Chain Wheels?

Field Proven Durability:

Backed by performance in over 200 installations across Asia and Middle East, with documented operating hours >20,000+ in cement clinker duty.

Induction-Hardened for Abrasive Handling:

All chain engagement surfaces are surface hardened to 52–55 HRC, minimizing wear under high-temperature, high-abrasion conditions.

Custom Geometry for OEM Chains:

Precisely matched to chain links for DIN 764 / DIN 766 and non-standard chain designs, ensuring low backlash and smooth meshing even at higher speeds.

Interchangeable with Aumund, Beumer, and OEM Profiles:

We provide drop-in replacements and enhanced upgrade designs for common OEM chain systems used in elevators and drag conveyors.

Available in Cast or Forged Types:

- Cast Wheels: Cost-effective for moderate duty

- Forged Wheels: High load, high-cycle applications with improved fatigue resistance

Precision from Design to Delivery

Our chain wheels are designed using CAD/CAM modelling and finite element validation, then CNC-machined and inspected to tight tolerances.

We offer:

- Detailed 2D/3D drawings

- Material test reports (MTC)

- Reverse-engineered solutions for legacy equipment

Contact CMECH:

Equip your plant with chain wheels that last.

Get a quote or request reverse engineering from your worn-out sprocket sample.

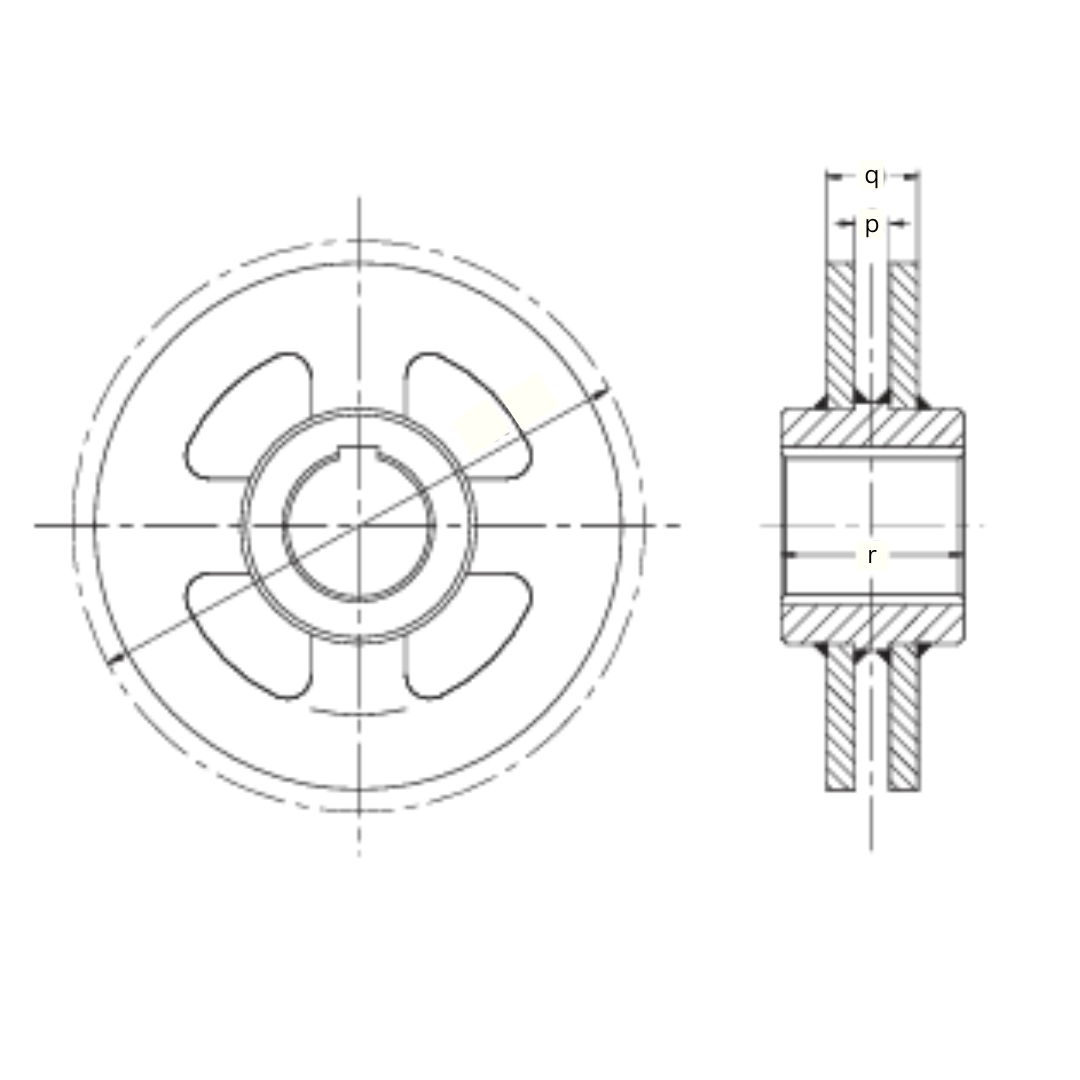

Table Chain Wheel

| PCD | d x t | Din | p | q | r |

| 144 | 10x 28 | 766 | 14 | 38 | 60 |

| 161 | 10x 28 | 766 | 14 | 38 | 60 |

| 179 | 10x 28 | 766 | 14 | 38 | 60 |

| 215 | 10x 28 | 766 | 14 | 38 | 60 |

| 135 | 10x 35 | 764 | 14 | 38 | 60 |

| 157 | 10x 35 | 764 | 14 | 38 | 60 |

| 179 | 10x 35 | 764 | 14 | 38 | 60 |

| 202 | 10x 35 | 764 | 14 | 38 | 60 |

| 224 | 10x 35 | 764 | 14 | 38 | 60 |

| 268 | 10x 35 | 764 | 14 | 38 | 60 |

| 185 | 13x 36 | 766 | 18 | 48 | 80 |

| 207 | 13x 36 | 766 | 18 | 48 | 80 |

| 230 | 13x 36 | 766 | 18 | 48 | 80 |

| 231 | 13x 45 | 766 | 18 | 48 | 100 |

| 259 | 13x 45 | 764 | 18 | 48 | 100 |

| 288 | 13x 45 | 764 | 18 | 48 | 100 |

| 256 | 14x 50 | Non-DIN | 19 | 49 | 100 |

| 288 | 14x 50 | Non-DIN | 19 | 49 | 100 |

| 320 | 14x 50 | Non-DIN | 19 | 49 | 100 |

| 174 | 16x 45 | 766 | 21 | 57 | 100 |

| 202 | 16x 45 | 766 | 21 | 57 | 100 |

| 231 | 16x 45 | 766 | 21 | 57 | 100 |

| 259 | 16x 45 | 766 | 21 | 57 | 100 |

| 288 | 16x 45 | 766 | 21 | 57 | 100 |

| 216 | 16x 56 | 764 | 21 | 57 | 100 |

| 252 | 16x 56 | 764 | 21 | 57 | 100 |

| 287 | 16x 56 | 764 | 21 | 57 | 100 |

| 323 | 16x 56 | 764 | 21 | 57 | 100 |

| 358 | 16x 56 | 764 | 21 | 57 | 100 |

| 247 | 16x 64 | Non-DIN | 21 | 57 | 100 |

| 328 | 16x 64 | Non-DIN | 21 | 57 | 100 |

| 369 | 16x 64 | Non-DIN | 21 | 57 | 100 |

| 409 | 16x 64 | Non-DIN | 21 | 57 | 100 |

| 256 | 18x 50 | 766 | 23 | 63 | 120 |

| PCD | d x t | Din | p | q | r |

| 288 | 18x 50 | 766 | 23 | 63 | 120 |

| 320 | 18x 50 | 766 | 23 | 63 | 120 |

| 243 | 18x 63 | 764 | 23 | 63 | 120 |

| 283 | 18x 63 | 764 | 23 | 63 | 120 |

| 323 | 18x 63 | 764 | 23 | 63 | 120 |

| 363 | 18x 63 | 764 | 23 | 63 | 120 |

| 403 | 18x 63 | 764 | 23 | 63 | 120 |

| 290 | 19x 75 | Non-DIN | 24 | 64 | 140 |

| 384 | 19x 75 | Non-DIN | 24 | 64 | 140 |

| 479 | 19x 75 | Non-DIN | 24 | 64 | 140 |

| 574 | 19x 75 | Non-DIN | 24 | 64 | 140 |

| 252 | 20x 56 | 766 | 25 | 65 | 140 |

| 287 | 20x 56 | 766 | 25 | 65 | 140 |

| 322 | 20x 56 | 766 | 25 | 65 | 140 |

| 315 | 20x 70 | 764 | 25 | 65 | 140 |

| 359 | 20x 70 | 764 | 25 | 65 | 140 |

| 403 | 20x 70 | 764 | 25 | 65 | 140 |

| 332 | 22x 86 | Non-DIN | 27 | 73 | 140 |

| 386 | 22x 86 | Non-DIN | 27 | 73 | 140 |

| 441 | 22x 86 | Non-DIN | 27 | 73 | 140 |

| 550 | 22x 86 | Non-DIN | 27 | 73 | 140 |

| 328 | 23x 64 | 766 | 28 | 74 | 140 |

| 369 | 23x 64 | 766 | 28 | 74 | 140 |

| 410 | 23x 80 | 764 | 28 | 74 | 140 |

| 461 | 23x 80 | 764 | 28 | 74 | 140 |

| 374 | 26x 73 | 766 | 32 | 82 | 160 |

| 420 | 26x 73 | 766 | 32 | 82 | 160 |

| 466 | 26x 91 | 764 | 32 | 82 | 160 |

| 524 | 26x 91 | 764 | 32 | 82 | 160 |

| 431 | 30x 84 | 766 | 36 | 82 | 200 |

| 671 | 30×105 | 764 | 36 | 96 | 200 |

| 454 | 36×101 | 766 | 42 | 96 | 200 |

| 726 | 36×126 | 764 | 42 | 112 | 220 |

| 680 | 42×118 | 766 | 50 | 130 | 220 |

| 847 | 42×147 | 764 | 50 | 130 | 220 |