Chain & Bucket Attachment

View Shackle Table Precision-forged chain shackles conforming to DIN 745 and DIN 5699 standards, designed specifically for chain bucket elevators operating in heavy-duty environments such as cement, steel, mining, and power plants. These shackles form the critical link between the chain and bucket, and are engineered to ensure maximum strength, dimensional precision, and long-term reliability under high mechanical and thermal stress.

| Standard | Description | Application Focus |

| DIN 745 | U-type forged shackles with threaded pin and nut assembly | General-purpose, high-load central chain elevators |

| DIN 5699 | Flat-profile shackles with compact geometry and low clearance | Tight bucket spacing and reduced PCD elevators |

Technical Features

| Component | Technical Highlights |

| Body | Drop-forged alloy steel, normalized and surface cleaned; high fatigue resistance under tensile and impact loads |

| Cross Pin | Heat-treated steel bolt, precision-ground and matched to bore for even stress transfer |

| Nut & Locking | Hex nut with spring washer or locking plate as per DIN standards; resists vibration loosening |

| Mounting Geometry | Designed to match the chain’s inside link width and pitch spacing for snug and aligned bucket attachment |

| Surface Protection | Supplied with anti-corrosion coating or hot-dip galvanized upon request for harsh environments |

Assembly & Spare Parts Supplied

Constromech provides complete shackle kits with:

- Forged shackle body

- Cross bolt/pin with matching hardness

- Nut and washer/locking plate

- Optional adapter plates for custom bucket interfaces

- Shims and spacers for field alignment corrections

- Full dimensional traceability and serial tagging

All components are match-marked and ready for installation. No re-drilling or machining required.

Operational Advantages

- Reliable Load Transfer

Optimized U or flat geometry maintains uniform stress distribution across chain links and bucket plates. - Reduced Downtime

Through-hardened pins and precision-machined bores reduce wear, elongation, and lateral play. - Extended Service Life

Self-locking assemblies withstand constant vibration and temperature cycles, reducing the risk of loosening. - Energy Efficiency

Compatible with various bucket geometries, adapter plates, and chain sizes from 10 × 28 mm to 38 × 144 mm. - Predictive-Maintenance Friendly

Modular and standardized design allows fast swap-out during shutdowns with basic tools.

Why Constromech Shackles?

| Feature | Benefit |

| Forging & machining | Full control over material traceability, heat treatment, and dimensional accuracy |

| Custom Configurations | Special widths, bolt lengths, or pin diameters available on request |

| OEM Compatibility | 100% match with standard DIN 764/766 round link chains and all leading bucket profiles |

| Ready Stock | Fast delivery on common sizes; expedited manufacturing for shutdown replacements |

| Engineering Support | Technical drawings, torque specs, and on-site guidance for critical applications |

Use Cases

- Clinker and slag elevators in cement and steel plants

- Raw material and limestone elevators in mining and crushing plants

- Fly ash and coal handling systems in thermal power stations

- Bulk storage and reclaim applications in ports and terminals

Fit. Lock. Elevate.

Shackles are built to handle the toughest conveying environments — with reliability, precision, and longevity engineered into every piece. Whether you’re installing a new elevator line or retrofitting an aging one, we deliver plug-and-play shackle solutions that exceed DIN standards.

Contact us today for detailed drawings, standard availability, or complete chain + shackle + bucket assemblies tailored for your project.

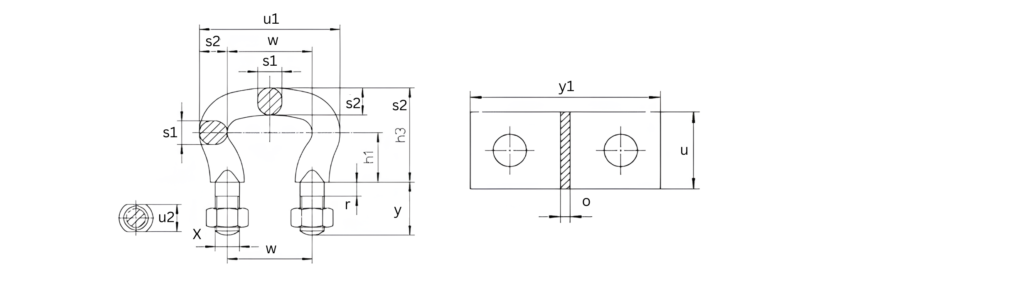

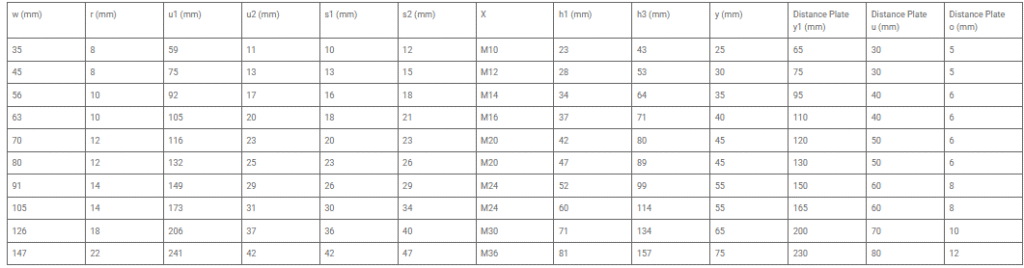

DIN-745 CHAIN SHACKLE

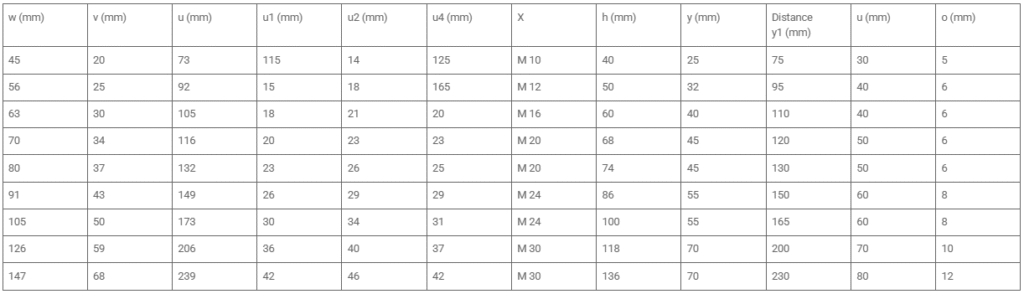

DIN-5699 CHAIN SHACKLE