Use Case Highlight

In a major coal power plant, retrofitting Constromech’s sensor suite on the bottom ash conveyors can lead to immediate benefits. The system can be caught developing issues like flight bar wear and chain tension abnormalities during operation, allowing maintenance during scheduled outages.

Over 12 months, unplanned conveyor outages can drop by roughly 75%, eliminating several emergency shutdown events. The plant can not only save on repair overtime but also avoid lost generation capacity that would have cost hundreds of thousands per incident.

Similarly, in a cement plant, our AI sensors on a deep pan conveyor can detect a pattern of roller failures early.

By addressing the root cause proactively, the plant can extend the conveyor’s uptime through the high-production season, translating to extra clinker output that bring in additional revenue while also deferring a costly overhaul to the next planned turnaround.

These examples illustrate how Constromech’s AI-powered monitoring directly boosts the bottom line:

Fewer surprises, more production hours, and a more strategic maintenance workflow!

From a competitive standpoint, adopting Constromech’s intelligent monitoring gives operators a clear ROI advantage.

It maximizes asset utilization (getting more output from existing equipment) and minimizes the chance of expensive, reputation-damaging failures. Plants can confidently push for higher throughput, knowing the sensor system will warn them before something breaks.

Maintenance teams move from firefighting to optimization, focusing on planned fixes and continuous improvement. Over time, the data collected can even guide design upgrades – for instance, identifying a particular pulley that frequently runs hot and suggesting a redesign or better cooling.

This continuous feedback loop helps in extending equipment life cycles and planning capital replacements more efficiently.

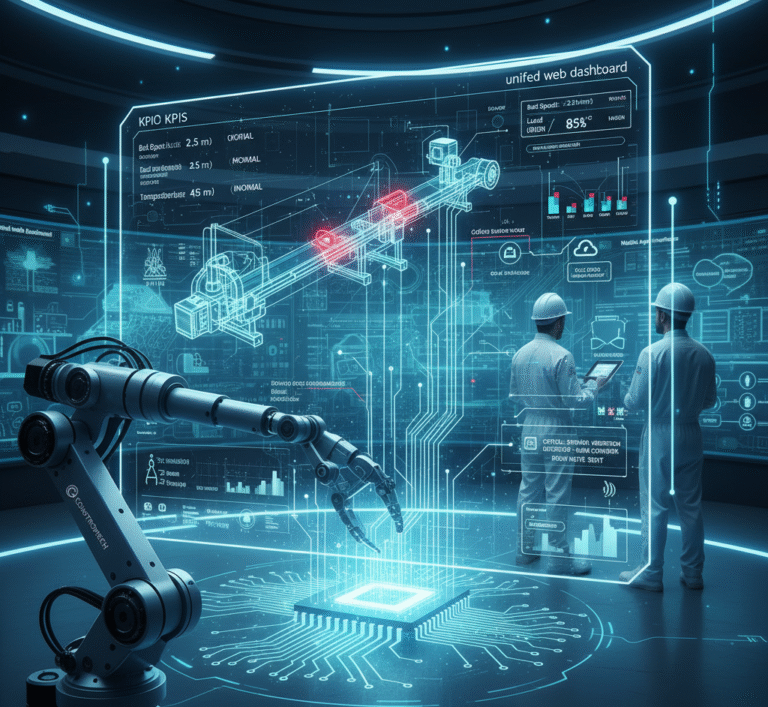

In summary, Constromech’s AI-powered sensor suites deliver a one-two punch:

Technical depth (full-spectrum, real-time monitoring with smart diagnostics) and practical results (cost savings, higher uptime, safer operations).

They embody the modern, data-driven approach to industrial maintenance, transforming traditional conveyors and elevators into intelligent machines that practically “take care of themselves.

” By choosing Constromech solution, industries ranging from mining to manufacturing are gaining peace of mind and a significant competitive edge – all while reducing their maintenance bills.

With its proven performance in harsh conditions and its scalable, customizable design, our AI-integrated monitoring platform is poised to become an essential component of reliable, efficient bulk material handling systems worldwide.

Don’t just react – predict and prevent

with Constromech’s intelligent sensor solutions for a new era of productivity