Bucket Elevator with Steel Cord Reinforced Rubber Belts

Our company offers steel cord reinforced rubber belts specially designed for high-performance bucket elevators, featuring heat-resistant construction for superior durability and operation efficiency.

Two belt grades are available: NT Grade – suitable for continuous operation up to 90°C with occasional peaks up to 100°C, and HT Grade – ideal for continuous operation up to 130°C with short-term peaks reaching 150°C.

The rubber cover layers serve as a protective barrier, shielding the internal steel cords from abrasive material contact and moisture, thereby preventing corrosion.

Each new belt is supplied with a surface hardness not exceeding 65 Shore A, ensuring flexibility and extended service life.

Belt lifespan is mainly influenced by operating temperature, as elevated heat accelerates rubber hardening, reducing flexibility over time.

Maintaining lower bulk material temperatures during operation significantly extends belt life and enhances long-term reliability.

It is advisable to measure the rubber surface hardness during every scheduled maintenance or at least once annually.

The belt should be replaced if surface hardness values exceed 95 Shore A, as this indicates advanced surface hardening.

The belt features a steel carcass reinforced with high-tensile steel cords arranged both longitudinally and transversely. Its specially designed elastic modules ensure excellent tracking stability and flexibility around pulleys.

A precision manufacturing process introduces rubber buffering layers between the steel cords, guaranteeing no direct contact between internal weft elements, thus enhancing fatigue resistance.

Two steel weft layers, formed by closely spaced steel cables embedded in the top and bottom covers, provide high transverse stiffness for exceptional tracking stability. This rigid reinforcement network also delivers superior tear resistance at bucket attachment points.

Both belt grades are available in nominal tensile strengths of 800, 1250, 1600, 2000, 2250, 2500, 2800, 3000, and 3500 N/mm of belt width, catering to diverse material handling requirements.

Bucket Elevator with Steel Cord Reinforced Rubber Belts – A-Type Belt Design

The base structure of the belt remains consistent, but two specific design variants are provided to accommodate different bucket attachment systems used by various OEMs.

A-Type Belt Configuration

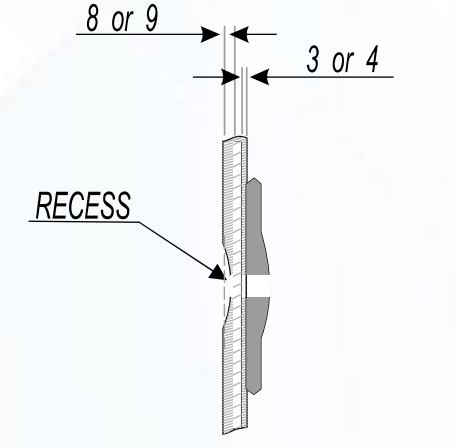

In the A-Type configuration, both the running surface and bucket attachment side have equal rubber cover thickness, typically 3 mm or 4 mm, depending on belt grade.

Buckets are fastened using M12×60 mm plate screws with a forged plate diameter of 38 mm. Each plate includes two forged locking projections on the inner face, ensuring a secure anti-rotation fit.

The back plate is embedded sufficiently into the rubber layer, preventing damage to the drive drum’s friction lining. The internal steel network structure provides strong load distribution, avoiding pull-through of fixation screws.

The bucket’s rear panel is designed with a contoured shape that allows the belt to flex and absorb deflection stresses introduced by the plate screws.

High-temperature resistant sealing strips with pre-tensioned lips are positioned between the steel cord belt and bucket rear panel. These prevent bulk material ingress, thereby protecting the belt from wear during pulley rotation.

The rubber sealing strip height is 140 mm or 170 mm, depending on bucket projection.

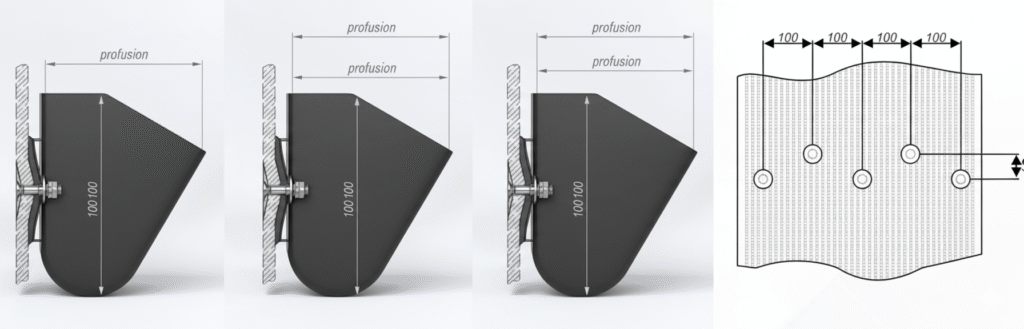

Depending on the bucket size and overhang, one or two rows of plate screw fixations are provided to withstand the bending torque generated by bucket protrusion.

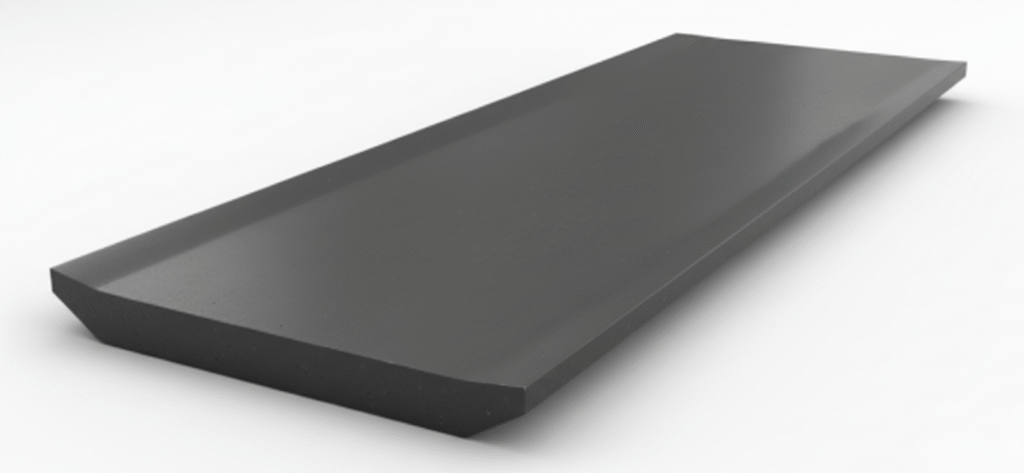

Each bucket plate is manufactured from 4 or 5 mm thick material, featuring a reinforcement lip along the entire front edge to enhance resistance against abrasive materials.

The optimized bucket profile guarantees clean, residue-free discharge under centrifugal action, ensuring efficient and continuous operation.

Bucket Elevator with Steel Cord Reinforced Rubber Belts

B-Type Belt Design & Fixation Details

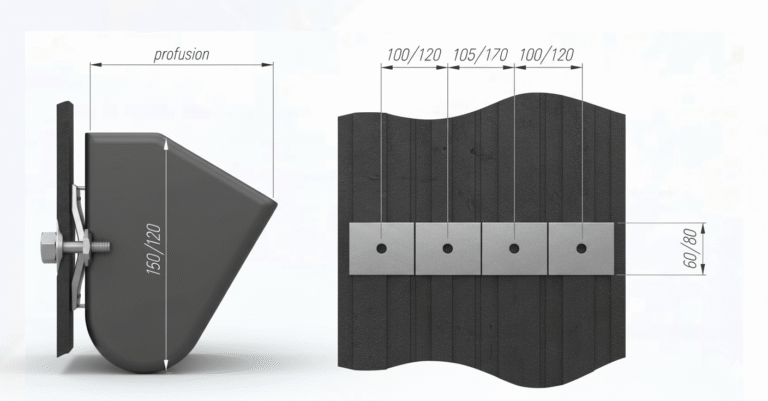

B-Type Belt The rubber covers on the running surface and the bucket attachment side are asymmetrically designed, meaning their thickness varies based on the required belt strength and operating load.

Buckets are fixed to the belt using forged back plates and countersunk head screws, tightened with hexagonal nuts featuring a special shoulder for secure locking.

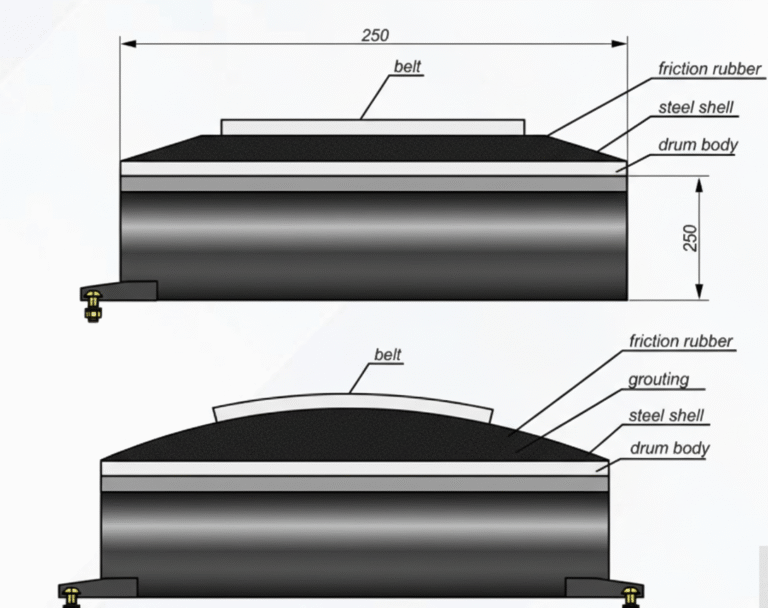

On the bucket side, the rubber layer thickness is 3 or 5 mm, while the running surface of the belt has a rubber thickness of 8 or 9 mm to form a recess. This recessed design fully houses the metal back plates, allowing smooth rotation and stress-free contact over the pulleys. The recess also helps reduce internal stress within the belt caused by compressed steel cord layers.

Profiled rubber distance strips, vulcanized directly onto the steel cord reinforced belt, work in combination with the bucket’s shaped rear panel to prevent bulk material intrusion in the belt–bucket interface, protecting the belt from damage during pulley rotation.

The bucket’s rear panel features a special contour that enables the belt to flexibly absorb deflection created when back plates penetrate the running surface, ensuring smooth and secure performance.

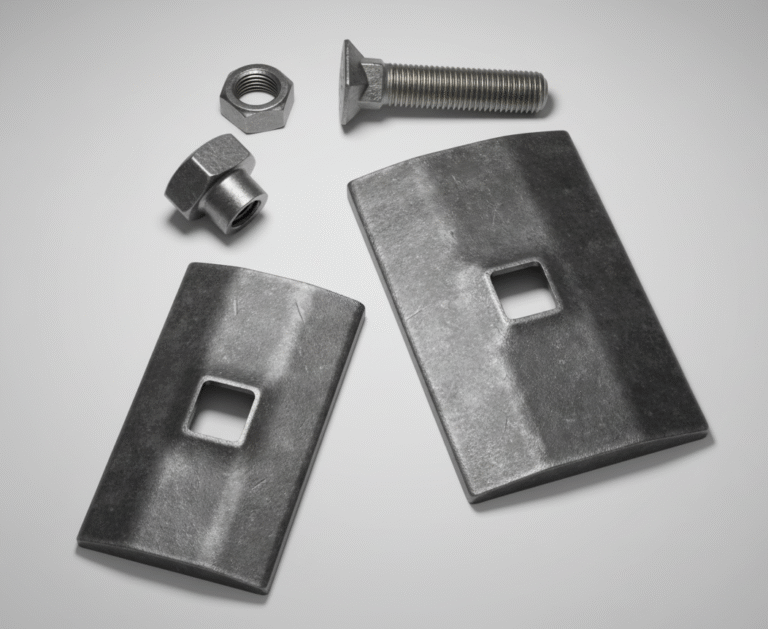

Buckets are mounted using a single row of forged back plates, which measure 160×99 mm or 80×119 mm, depending on the bucket width and projection.

Each bucket plate is fabricated from 4 or 5 mm thick steel, featuring reinforced edges and a beveled discharge front to handle abrasive materials effectively. The optimized bucket geometry promotes residue-free discharge through centrifugal action, maximizing efficiency.

SECTION — DRIVE DRUM FRICTION LINING & TAGGING TYPES

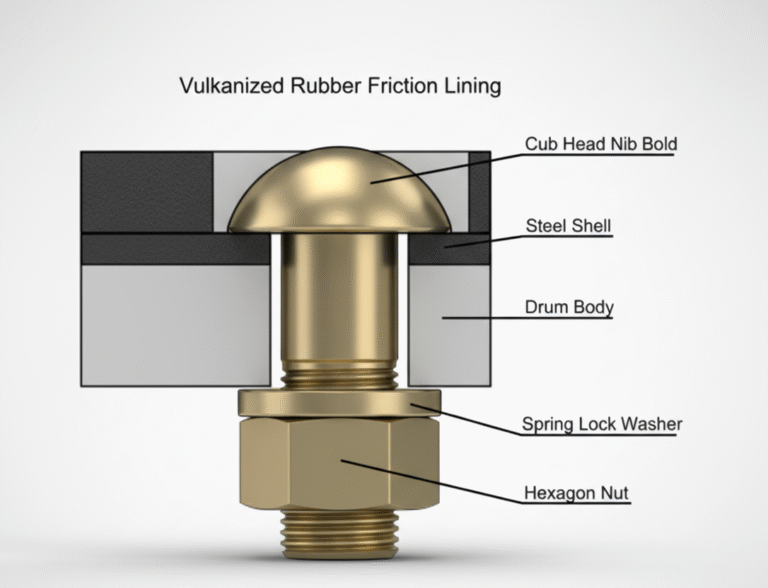

Drive Drum Friction Lining (CMECH Type) The CMECH drive drum rubber lining is engineered with optimized design geometry and produced under strict quality standards, ensuring long-term reliability and consistent performance.

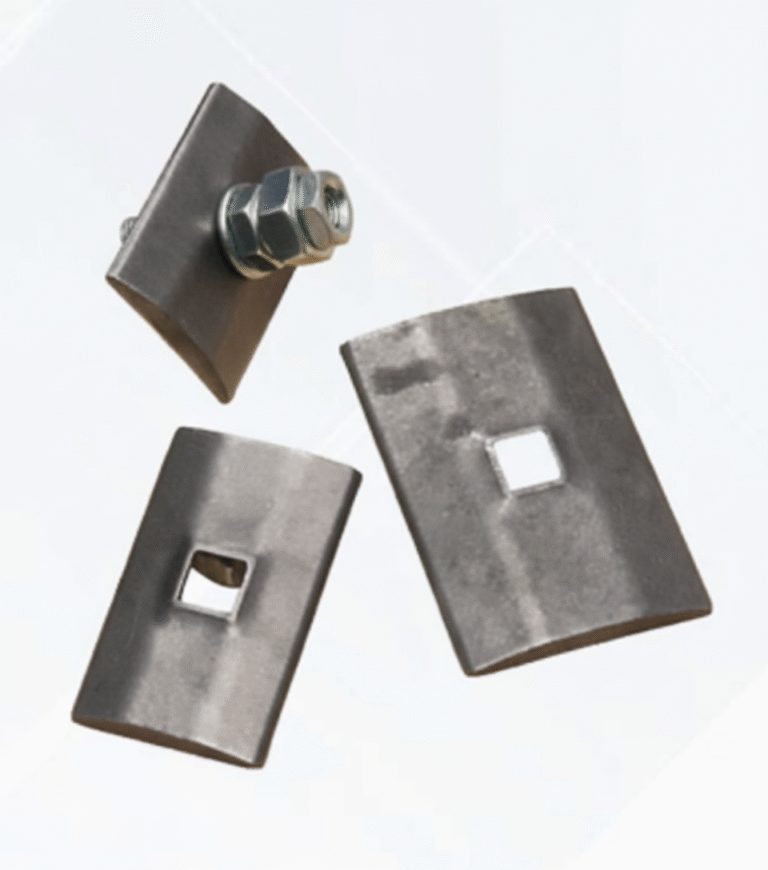

The lining consists of highly wear-resistant rubber vulcanized onto steel shells, offering exceptional durability. Its segmented construction allows for quick and efficient replacement during maintenance.

A precision-molded surface pattern ensures excellent traction between the belt and drum, while minimizing surface wear on both the belt and friction lining.

Specially designed fixing holes enable fast and secure installation using cup head nib bolts, simplifying assembly and maintenance.

The standard CMECH friction lining design follows the specifications above, but two drum configurations are offered depending on the belt and bucket attachment type used.

A-Type Tagging – In the A-Type configuration, the trapezoidal drum shape ensures accurate centering of the steel cord belt. This geometry is achieved through precision grooving using high-strength polymer inserts (as shown in the adjoining illustration).

B-Type Tagging – The B-Type lining utilizes a full drum profile formed with custom hard-plastic profiling. This design provides uniform belt centering and contact, improving drive efficiency and reducing belt slippage (see figure).

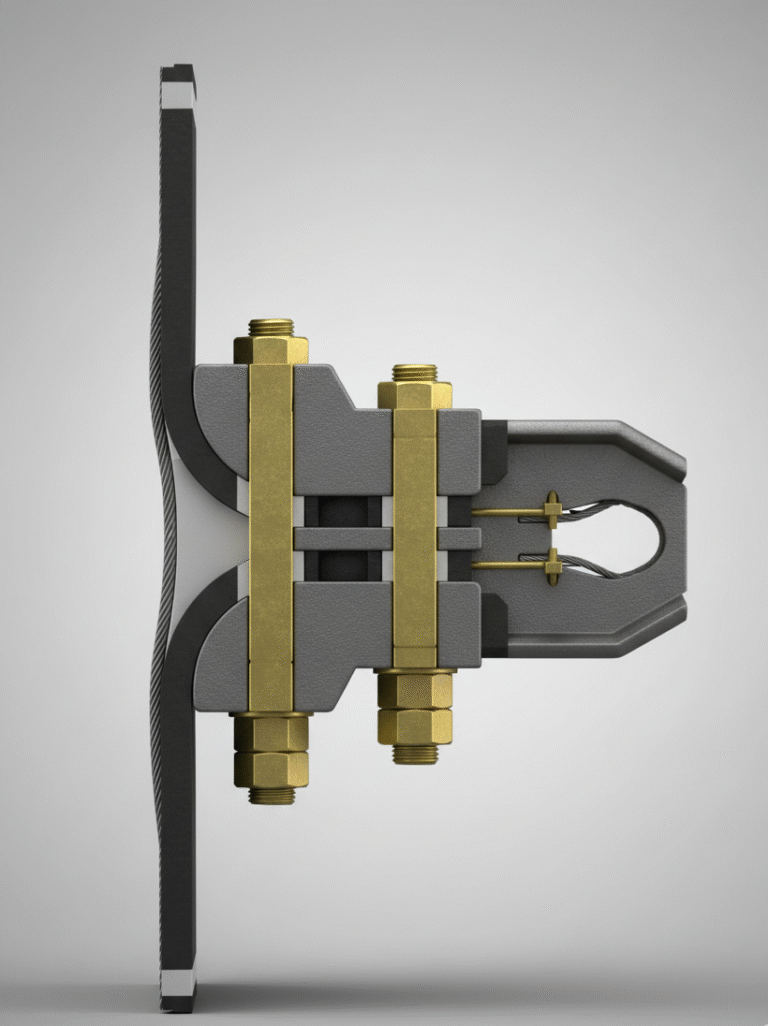

CMECH CLAMPING CONNECTION

CMECH Belt Clamping Connection The clamping system plays a role equally vital to the belt’s overall strength. CMECH designs its clamping connections using the latest engineering methods and lightweight, high-tensile materials to achieve maximum strength and reliability.

The three-part clamping assembly for joining belt ends is constructed from precision aluminum profiles. It includes pre-drilled holes for installation hardware such as high-tensile bolts, nuts, and washers. Along with this, a resin-based sealing compound and rope clamps are provided for sealing and securing the steel cord ends.

The belt-end preparation and final on-site assembly of the clamping connection should be executed or supervised by a qualified CMECH engineer to ensure correct alignment and safety.

Bucket fixing holes are precision-punched during the assembly stage to maintain alignment. Any traction cords trimmed during this process are excluded from strength calculations. For belt-end clamping, pre-bent steel cord ends are supplied with drilled holes to fit the clamping system.

Belt Strength Calculation (Example):

For a bucket elevator using a steel cord-reinforced rubber belt (HT1 type) with nominal tensile strength of 1250 N/mm, carrying belt width of 1200 mm, and clamping width of 800 mm: each belt contains 32 steel cords (2×20 type), each 2.1 mm in diameter. The rubber spacing between cords is 10 mm to the belt edge. The punched hole diameter is 13 mm, but a 25 mm hole diameter is considered for safety factor calculations.

Sample Calculation:

Carrying width = 850 mm × 25 mm × 2.75 mm = 625 mm

Actual belt strength per width = 625 mm × 625 N/mm = 590 kN

For bolt-end connection = 500 mm × 585 N/mm = ≈0.625 kN