Wheel Rim & Shaft Assembly Table

Complete “fit-and-run” wheel-rim and shaft packages for chain bucket elevators. Unlike conventional toothed sprockets, these toothless chain wheels (also called “pocket wheels”) use modular steel segments to cradle each chain link—reducing point wear, shock loading, and noise.

Product Families & Nomenclature

| Series | Segments / Wheel | Typical Duty | Key Dimension Tags* |

| COA | 12 | High-capacity clinker, slag & iron-ore elevators | PCD, p, t, m, n, o, p, l |

| CBA | 6 | Medium-duty limestone, coal & raw-meal lifts | PCD, d, t, m, n, o, p, l |

Construction Features

| Component | Technical Detail | Benefit |

| Rim Segments | Precision-machined alloy steel, case-hardened 45–55 HRC | High wear resistance; easy individual replacement |

| Pocket Geometry | Contoured to chain Ø & pitch; ±0.25 mm pocket tolerance | Uniform load, low chain slap, quieter running |

| Split Hub | Two-piece or fit hub keyed to shaft | Fast swap-out with minimal lift of neighbouring equipment |

| Wheel Body | Stress-relieved steel plate or cast center disc | Lightweight yet rigid; balanced to ISO G 6.3 |

| Shaft | Hardened journals, ground to H7; supplied drilled & tapped | Direct fit into CMECH or OEM bearing blocks |

| Fastener Set | Customised grade bolts, washers, torque chart supplied | Secure clamp force under vibration & heat cycles |

Performance Advantages in Elevator Service

- Extended Chain Life – Pocket support along ~120° of the link circumference lowers bearing pressure by up to 40 % versus toothed wheels.

- Reduced Maintenance – Segments can be swapped individually through the elevator casing window—no shaft removal required.

- Lower Noise & Vibration – Tooth-free engagement eliminates impact, cutting sound pressure levels by 6–8 dB.

- Hot-Material Capability – COA series segments maintain hardness above 350 °C, ideal for clinker exits.

- Energy Savings – Smooth rolling contact trims motor amperage, typically saving 3–5 % drive power.

Supplied-as-One “COA / CBA Assembly Kit”

- Wheel rim (segmented) pre-mounted on hub

- Machined shaft with keyways, endcaps & retainer nuts

- Spacer rings / shims to match exact elevator casing width

- Plummer-block bearings (optional) greased & sealed for 200 °C continuous duty

- Installation torque sheet, 3-D model & QA dossier (material, hardness & balance certificates)

Arrives palletised, match-marked and ready to bolt in—fit, torque, run

Why Choose Constromech?

| Advantage | What It Means for Your Plant |

| Made-to-Measure | Any PCD from 400 mm to 1 000 mm; custom pocket shapes for worn chains |

| Rapid Segment Supply | Stock sets for popular 16 × 64 mm & 22 × 86 mm chains—ship in 48 h |

| One-Stop Package | Chains, wheels, shafts, bearings, boot blocks and shackles from a single source |

| Field Engineering | Alignment, vibration analysis and torque verification on request |

| Lifecycle Cost Down | Lower spare-parts spend and 50 % faster turnaround than conventional wheels |

Ready to Upgrade?

Email us your chain size, elevator height (C/C) and drive power. Constromech will return a drop-in wheel-rim & shaft proposal—complete with CAD model, strength calculations and delivery schedule—within 72 hours.

Elevate with confidence. Choose Constromech wheel-rim assemblies for maximum uptime, minimum fuss.

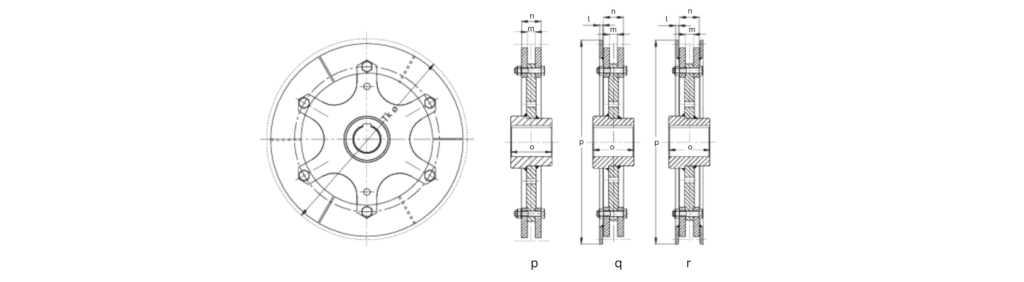

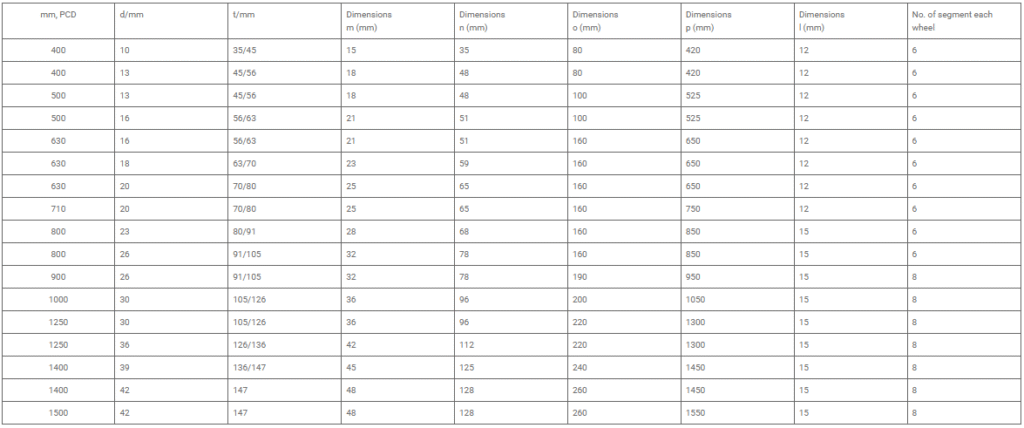

Specifications of toothless chain wheels with modular steel segments, CMECH Type COA series

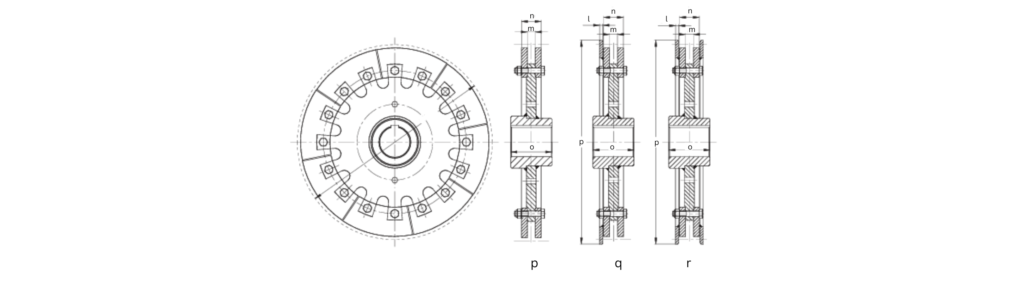

Specifications of toothless chain wheels with modular steel segments, CMECH Type CBA series