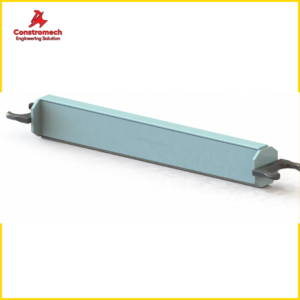

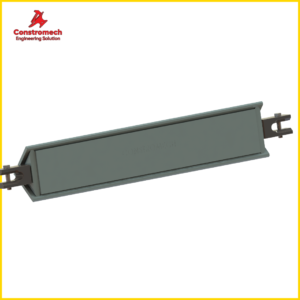

Scrapper Bar

Engineered for Extreme Conditions. Fabricated for Long Life.

Product Construction

Structure: Scrapers are fabricated using heavy-duty structural channels, angles, or rectangular pipes, chosen for high mechanical load capacity and corrosion resistance asper their yield strength and higher fatigue points.

Scraping Surface:

- Cladded with welded-on wear-resistant hard plates, typically in the 440–500 BHN range, tailored to the ash abrasiveness and plant requirement.

- Hard-plating ensures maximum lifespan even under high-temperature and abrasive slurry environments.

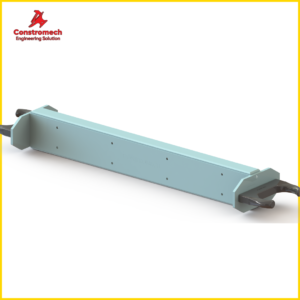

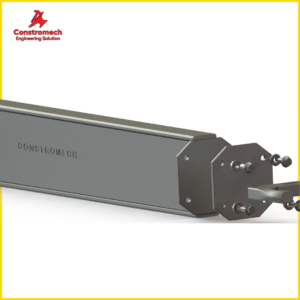

End Connectors:

- Manufactured from forged alloy steel to match the hardness, tensile and fatigue properties of the paired round link chains.

- Heat-treated up to 55 HRc, chemically matched to prevent interface erosion and ensure mechanical integrity.

Key Advantages

| Feature | Benefit |

| Fabricated Modular Design | Easy field replacement and adaptable to various conveyor widths |

| Welded Hard Cladding (440–500 BHN) | Exceptional abrasion resistance in high-wear bottom ash environments |

| Forged & Heat-Treated Connectors (up to 55 HRc) | Matched mechanical performance with round link chains |

| Custom Lengths & Profiles | Precision-fitted to trough design and material characteristics |

| Compatibility | Works seamlessly with standard submerged and dry bottom ash conveyor systems |

Ideal for

- Submerged Chain Conveyors (SCC)

- Dry Bottom Ash Handling Systems

- Power Plants up to Ultra Supercritical Grade

Backed by decades of field-tested experience, our scraper bars are in active deployment across leading Indian and international thermal power plants.

Let’s Talk Performance

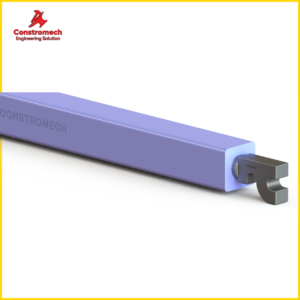

Fabricated Pans for Dry Ash Conveyors

Product Highlights

Heavy-Duty Fabrication

Crafted from structural channels, angles, or rectangular steel pipes for top-tier structural integrity.

Designed to withstand thermal shock from red-hot ash and large slag lumps.

Integrated Wear Protection

Welded-on hard plates rated 440–500 BHN across the pan bottom and sides.

Customizable hardness grades for specific plant operating conditions ensure minimal wear.

Round-Link Chain Compatibility

Built-in forged alloy steel connectors are heat-treated to ≈55 HRc, chemically and mechanically matched for seamless integration with your chain conveyors.

Modular & Service-Friendly

Pans are bolt-together modular units—fast and easy swap-out during maintenance, reducing downtime.

Smooth interiors reduce material hang-up and eliminate ash retention zones.

Key Benefits

| Feature | Benefit |

| Precision fabrication & weld quality | Enhanced structural strength; handles heavy ash loads and impacts |

| Wear-resistant hard cladding | Maintains long service life under abrasive conditions |

| Compatible connectors | Ensures secure fit with round-link chains, prevents fatigue |

| Service modularity | Enables rapid field assembly and maintenance |

| Adapted for dry conveyor cooling | Designed for dry ash in forced draft air-cooled environment |

Ideal Applications

- Dry bottom ash systems in thermal power plants

- Round-link chain conveyors using air-cooling

- Retrofit and new-build systems aiming to eliminate wet ash handling

Why Choose Constromech?

With deep expertise in bottom ash systems, we engineer pans that exceed the rigorous specifications. Our deliverables include:

- Customized pan sizes, wall thicknesses and wear plate configurations

- One to One replacement with OEM fitment

- Heat-treated connectors compatible with your chain assemblies

- Full QC, material traceability, fabrication documentation, and onsite support

Ready for Performance & Reliability?

Fuel your pan requirements with Constromech engineering-grade design and fabrication. Contact us to match pan dimensions, material grades, connector specifications, and deliverables for maximum uptime.