Sprocket and Shaft Assembly

Complete, ready-to-install drive and tail sprocket assemblies for chain bucket elevators & chain conveyor. Each kit ships fully machined, dynamically balanced, and test-mounted so your maintenance crew can “fit, torque, and run” with minimal shutdown time.

What’s in a Constromech Assembly?

| Sub-assembly | Standard Scope | Optional / Spare Items |

| Sprocket Rim (drive / idler) | One-piece or 3-/6-piece segmented rim in quenched-and-tempered alloy steel; precise Pitch Circle Diameter (PCD) matched to chain size | Spare rim segments; full replacement rims |

| Replaceable Teeth (DDA / ASP profiles) | Bolt-on or weld-on teeth, case-hardened to 50–55 HRC for extreme wear life | Extra tooth sets, shim plates, mounting hardware |

| Hub | CNC-bored, key-seated, and stress-relieved steel hub; concentricity ≤ 0.03 mm | Split hubs for confined installs; taper-lock bushings |

| Shaft | Solid or hollow alloy-steel shaft, optional induction-hardened journal zones; supplied with keyways and endcaps | Spare shafts, woodruff keys, locking assemblies |

| Bearing Blocks | Plummer blocks with double-row spherical-roller bearings; factory-packed with high-temp grease | Labyrinth seals, felt rings, bearing spacers |

| Sealing System | Dual labyrinth or contact seals + flinger discs to keep dust and clinker fines out of bearings | Spare seal kits, grease nipples |

| Torque Limiter / Backstop (drive end) | Optional overrunning clutch or hydraulic torque arm for anti-rollback protection | Replacement backstop elements |

| Fasteners & Shims | 8.8 or 10.9 grade bolts, nuts, and spring washers to DIN standards | Full bolt packs, spacer kits |

All components arrive match-marked and serialized for traceability and ease of re-ordering.

Technical Design Highlights

- Finite-Element-verified tooth geometry ensures uniform stress distribution and maximizes chain and tooth life.

- Pitch accuracy: PCD tolerance ±0.25 mm; axial run-out ≤ 0.05 mm—guarantees smooth chain engagement and reduced vibration.

- Induction-hardened tooth flanks (4–6 mm case depth) resist abrasive wear from clinker, slag, and limestone.

- Dynamic balancing to G 6.3 (ISO 1940-1) at operating speed prevents premature bearing failure on high-RPM return stations.

- Surface shot-peening of rims and teeth improves fatigue strength by up to 30 %.

- Pre-greased & plug-sealed bearings mean no field lubrication before start-up.

Operational Advantages

- Plug-and-Play Installation

- Pre-assembled shaft–hub–bearing package drops straight into existing pillow-block pedestals or flange interfaces.

- Reduced Downtime

- Segmented rims and replaceable teeth allow one-man replacement without pulling the shaft.

- Extended Service Life

- Superior metallurgy, deeper case depth, and precision machining cut wear rates, slippage, and chain whip.

- Energy Efficiency

- Perfect tooth–chain meshing reduces friction losses and motor load.

- Predictive-Maintenance Friendly

- All wear parts (teeth, seals, bearings) are stocked as spares with identical serial references; vibration and temperature points clearly indicated on the hub for sensor mounting.

Why Buy from Constromech

| Advantage | What It Means for You |

| Full Customisation | Any chain size (10 × 28 mm → 38 × 144 mm), any tooth count, solid or split rims, exotic alloys for corrosive media |

| Integrated Supply | Chains, sprockets, shafts, hubs, shackles, buckets, and fastening hardware from a single source—no compatibility guesswork |

| Rapid Turnaround | Standard assemblies ship in 1–2 weeks; emergency express rebuilds within 72 hours |

| Certified Quality | ISO 9001 shop, ultrasonic weld inspection, 200 % proof-load test, material & heat-treatment certificates supplied |

| On-Site Support | Alignment supervision, torque-check commissioning, and operator training available worldwide |

Upgrade Path & Retrofits

Whether you’re modernising a 40-year-old clinker line or building a new 120 m-high elevator, Constromech delivers turnkey sprocket-and-shaft kits that slot straight into your casing—with zero field machining and minimal alignment work.

Ready to maximise uptime?

Contact Constromech for drawings, finite-element stress reports, or a fast quotation tailored to your elevator geometry and duty cycle.

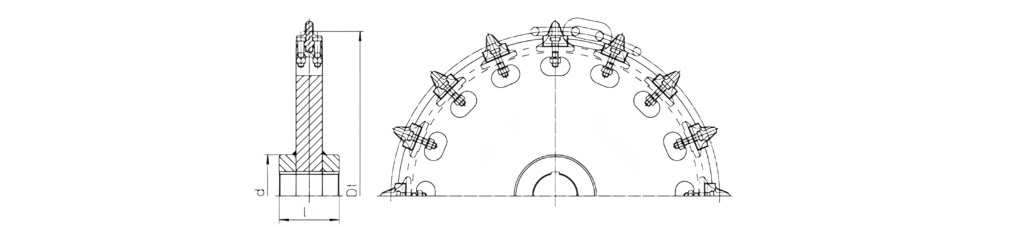

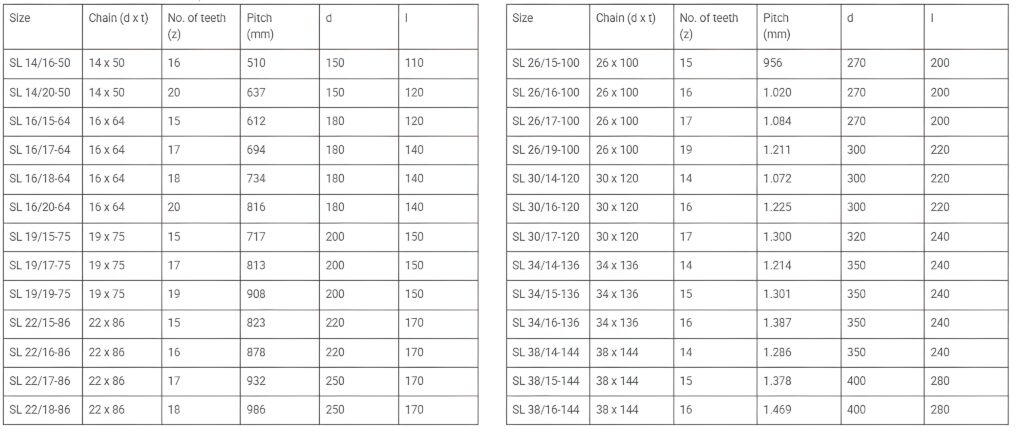

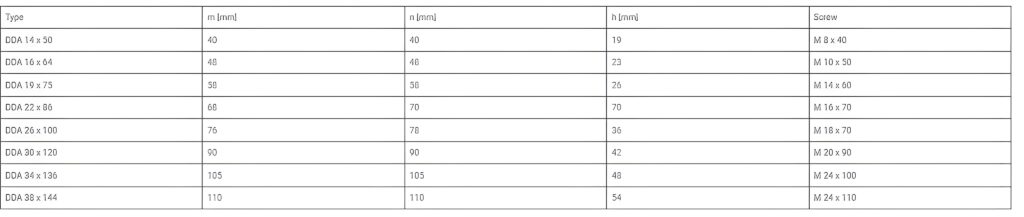

SL DRIVE SPROCKET TABLE

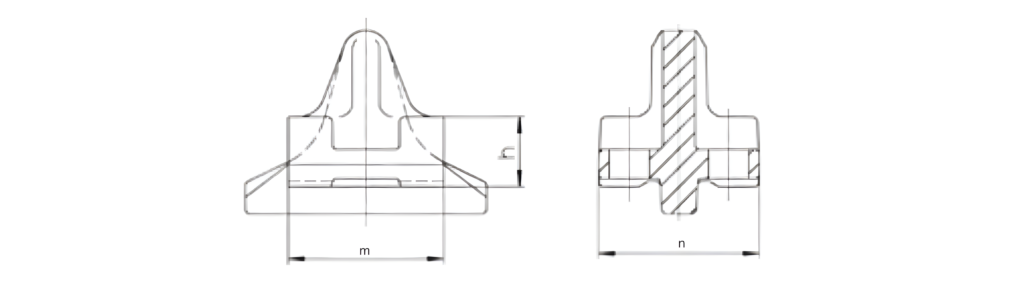

DDA SPROCKET TOOTH

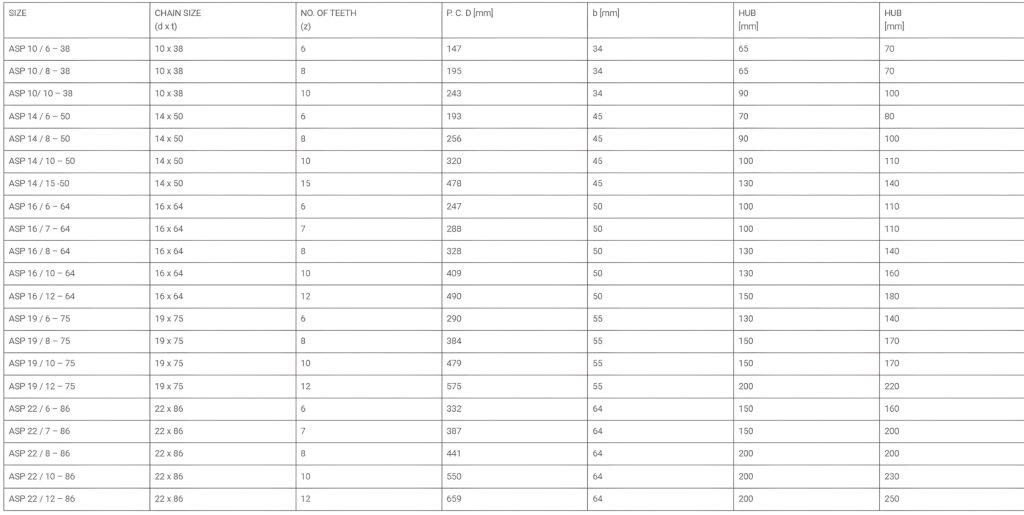

ASP CHAIN SPROCKET