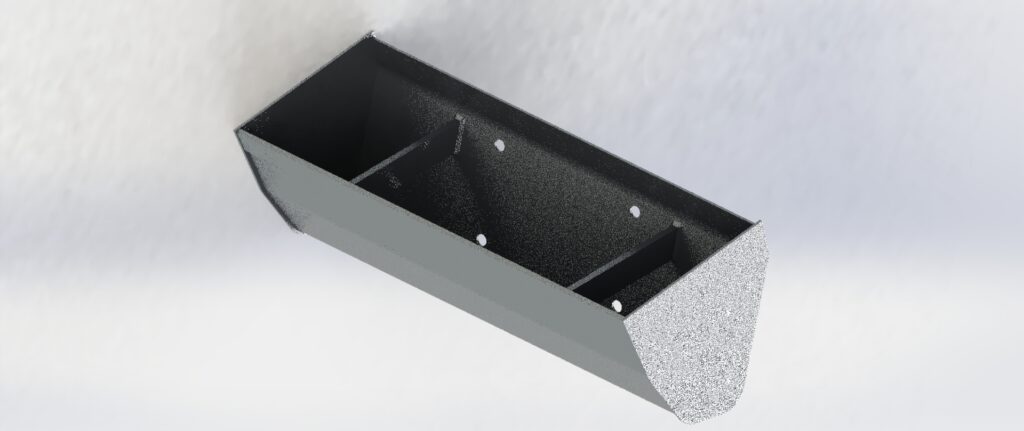

Fabricated Elevator Buckets for Bulk Material Handling

Constromech offers rugged fabricated elevator buckets designed to handle the toughest conveying tasks across industries such as cement, steel, mining, thermal power, and fertilizer. Engineered for both chain and belt bucket elevators, our buckets are made from high-tensile steel with precision-forming to ensure uniform material discharge, dimensional integrity, and long wear life.

Designed for Demanding Applications

Whether you’re elevating clinker, fly ash, slag, iron ore, gypsum, or granular fertilizer, Constromech buckets deliver:

- High volumetric efficiency

- Abrasion and impact resistance

- Precise mounting fit and smooth material flow

- Compatibility with all standard attachment types

Material & Manufacturing Highlights

- Fabricated from wear-resistant carbon steel or optional SS304/SS316

- Reinforced corners and continuous welded seams for maximum strength

- Anti-clogging design for sticky or fine materials

- Optional hard-facing or ceramic lining for extended wear life

- Powder coating or galvanizing available for corrosive environments

Compatible with Chain & Belt Elevators

Our buckets are suitable for:

- Central chain bucket elevators in clinker and limestone handling

- Double-strand elevators for blast furnace slag

- High-lift belt elevators in power plant ash conveying

- Fertilizer industry blending and packaging systems

Why Choose Constromech Buckets?

- Heavy-duty construction for extreme plant conditions

- Fully compatible with all standard chain and belt systems

- Designed to ensure consistent bucket spacing and load balance

- Faster installation with accurate hole pitch and mounting alignment

- Competitive pricing and Made in India quality assurance

Get Your Bucket Configuration Today

Whether you’re designing a new elevator or replacing worn-out buckets, our team is ready to assist with bucket selection, custom engineering, and supply scheduling.

Contact our experts today!

Table- Fabricated Elevator Buckets

| Bucket Size (W × H mm) | Depth (D) | Hole Pitch (A) | Hole Ø (mm) | Capacity (Ltrs) |

| 200 × 150 | 150 | 150 | 8 | 2.5 |

| 250 × 200 | 180 | 200 | 10 | 4.2 |

| 300 × 250 | 200 | 230 | 10 | 6.8 |

| 350 × 250 | 220 | 250 | 12 | 8.5 |

| 400 × 300 | 250 | 300 | 12 | 12 |

| 450 × 315 | 280 | 350 | 12 | 15 |

| 500 × 355 | 300 | 400 | 14 | 18.5 |

| 560 × 400 | 320 | 450 | 14 | 22 |

| 630 × 450 | 350 | 500 | 16 | 30 |

| 710 × 500 | 400 | 560 | 16 | 40 |

| 800 × 560 | 450 | 630 | 18 | 52 |

| 900 × 600 | 480 | 700 | 20 | 65 |

| 1000 × 630 | 500 | 800 | 22 | 78-85 |