Boot Bearing

Boot bearing assemblies designed to support and guide the boot shaft in chain and belt bucket elevators. These assemblies are critical in maintaining shaft alignment, rotational smoothness, and ensuring mechanical integrity in the dusty and high-load environment at the elevator’s base.

We offer ready-to-fit bearing blocks and matching bushings, tailored for specific shaft diameters and load classes—compliant with demanding operating conditions in cement, mining, steel, and thermal power sectors.

Assembly Overview

Each boot bearing assembly typically includes:

| Component | Function |

| Bearing Block Housing | Structural support for shaft, bolted to elevator base plate; includes bore for bush |

| Bronze or cast steel Bearing Bushing | Precision insert that supports shaft rotation and absorbs wear |

| Dust & grease seals (optional) | Protects bearing bore from contaminants, enhances lubrication retention |

| Base Plate and Bolting Set | Mounting hardware pre-aligned for bolt-on installation on elevator casing |

Technical Features (As per CMECH Design)

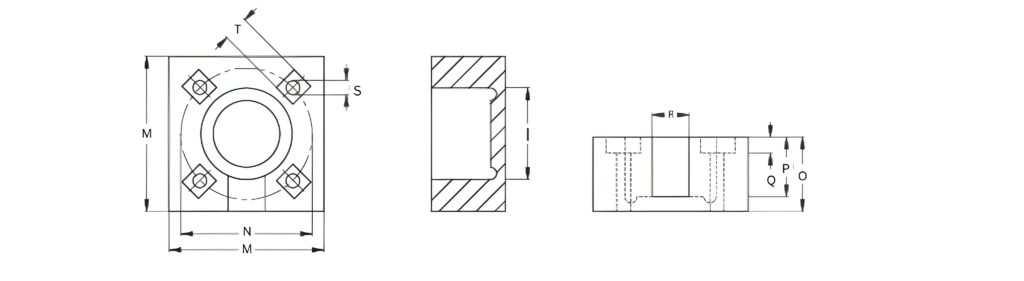

Bearing Block (CBB Series)

- Machined from high-strength cast steel or fabricated alloy steel plate

- Supplied with pre-drilled and tapped mounting holes, face machined for flatness

- Designed for easy access and fast replacement during shutdowns

- Available sizes:

- CBB 18-4: Shaft housing Ø52 mm, Load capacity up to 700 kg

- CBB 18-11: Shaft housing Ø55 mm, Load capacity up to 1200 kg

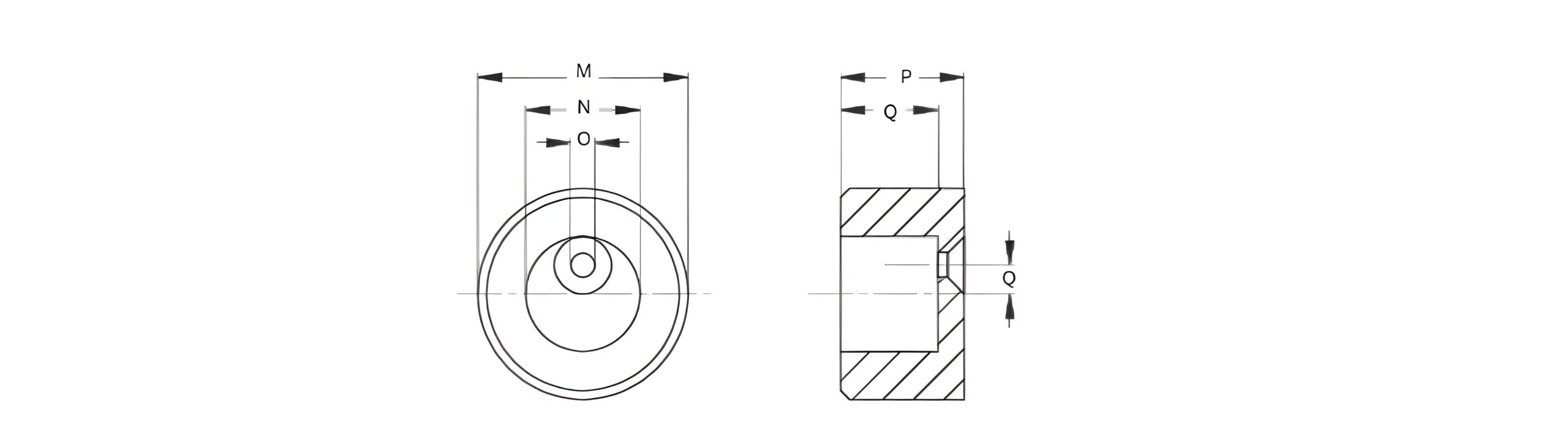

Bearing Bush

- Replaceable bushing made from cast or alloy steel

- Fine surface finish on ID (inner diameter) ensures minimal friction and smooth shaft rotation

- Double-step seating design (Q & R dimensions) for secure fit and easy extraction

- Precision matched to block and shaft journal — available in sizes to match 52–55 mm shaft diameters

Performance & Application Benefits

| Feature | Advantage |

| Anti-Friction & Self-Cleaning Geometry | Mitigates dust ingress and reduces the need for frequent maintenance |

| Compact Footprint | Fits even in restricted elevator pit areas with zero compromise on load capacity |

| Fully Machined Seating & Centreline Matching | Guarantees parallel alignment and vibration-free operation at high speeds |

Why Source from Constromech?

- In-House Precision Manufacturing

All bearing blocks and bushes are CNC-machined for dimensional repeatability and load tolerance. - Material Traceability & Load Testing

Supplied with certificates of material origin, hardness testing, and max-load validation (up to 1.2 tons per assembly). - Rapid Delivery & Spare Availability

Stock availability for CBB 18-4 and CBB 18-11; other sizes custom manufactured in 7–10 working days. - Custom Assembly for Boot Shaft Systems

We offer full boot shaft kits including:- Shaft (machined ends and journal zones)

- Bearing block and bushings

- Locking collars / grub screws

- Bolt sets for mounting

- One-Stop Support

Engineering support for bearing selection, field alignment, and shaft installation guidelines ensures faster commissioning and greater equipment longevity

Applications

- Cement plants (clinker elevators, raw meal lifts)

- Thermal power stations (fly ash return elevators)

- Fertilizer and chemical handling units

- Aggregate and quarrying bucket elevators

- Retrofit kits for older OEM elevators

Fit-and-Run Kits from Constromech

Whether upgrading an aging boot section or building a new bucket elevator from scratch, CMECH boot bearing assemblies are built to deliver performance, reliability, and operational ease — all with zero compatibility issues and engineered precision.

Reach out to our technical sales team for drawings, load recommendations, or a quotation for complete boot shaft kits customized to your plant layout.

Boot Bearing Table

Dimensions of CMECH bearing blocks for bucket elevators

| Type | M | N | O | P | Q | R | S | T | I |

| CBB 18-4 | 178 | 165 | 82 | 65 | 18 | 52 | 17 | 30 | 112 |

| CBB 18-11 | 230 | 203 | 108 | 90 | 20 | 55 | 21 | 34 | 138 |

Dimensions for CMECH bearing bushes

| Type | M | N | O | P | Q | R | max Load | min load |

| CBB 18-4 | 110.2 | 60 | 17 | 64 | 54 | 15 | 700kg | 50-60 |

| CBB 18-4 | 110.2 | 74.5 | 21 | 64 | 54 | 15 | 700kg | 50-60 |

| CBB 18-11 | 135.4 | 87.3 | 21 | 88.9 | 80 | 27 | 1200kg | 50-60 |

| CBB 18-11 | 135.4 | 100 | 21 | 88.9 | 80 | 27 | 1200kg | 50-60 |