DPC Rollers for Deep Pan Conveyors

Reliable Chain Support. Engineered for Cement Plant Demands.

Deep Pan Conveyor (DPC) Rollers are built to operate under extreme industrial conditions where high heat, dust, and impact loads are common — especially in cement plants. These rollers ensure smooth chain movement, reduce component wear, and help maintain consistent conveying in kiln feed, clinker transport, and ash handling systems.

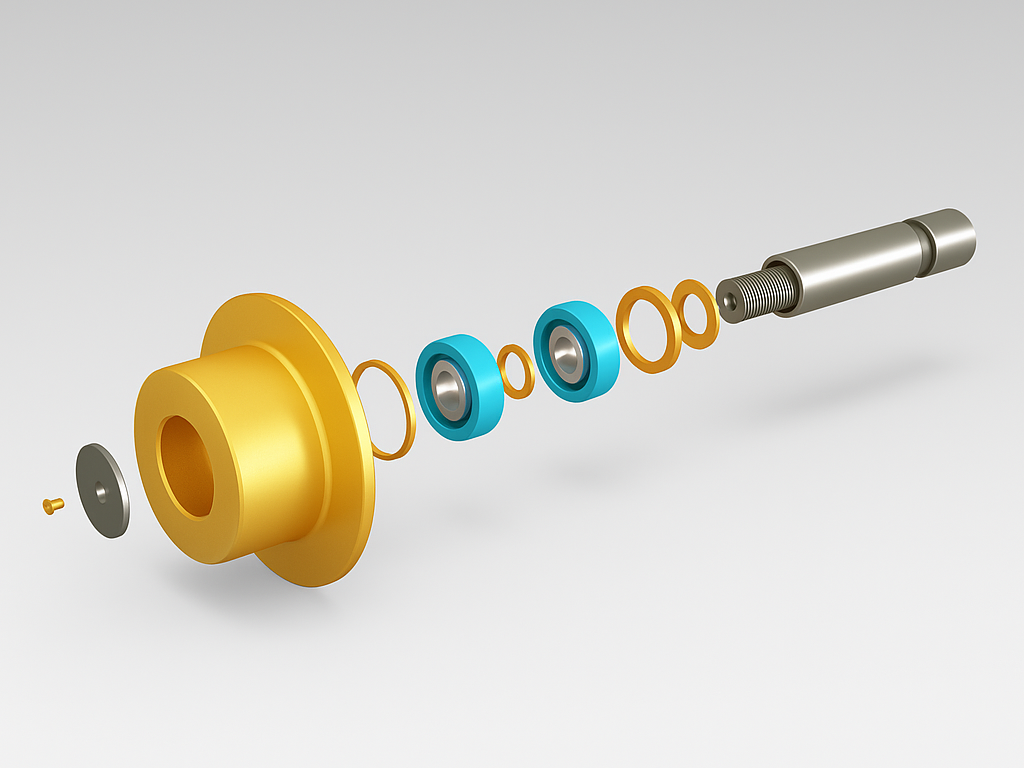

Product Construction:

| Component | Description |

| Roller Body | Forged or machined from heat-treated alloy steel for structural durability |

| Bearings | Pre-lubricated deep groove or spherical bearings, sealed for long life |

| Seals | Equipped with labyrinth or reinforced rubber seals to block dust and debris |

| Mounting Shaft | Precision-machined shaft with keyed or slotted ends for secure fitment |

Key Features & Benefits:

| Feature | Benefit |

| Hardened Surface (up to 55 HRC) | Resists abrasive wear and extends service life |

| Sealed Bearing Assembly | Reduces maintenance and ensures reliable rotation |

| Standard & Custom Sizes | Available for common pan widths and custom configurations |

| High Shock Load Resistance | Ideal for heavy start-stop conveying applications |

Application Areas

– Kiln feed conveyors in cement plants

– Clinker drag conveyors

– Deep pan conveyors for raw meal and additives

– Ash handling conveyors in thermal systems

Ready to Ship. Ready to Perform

Our deep pan conveyor parts are engineered as a complete solution — from chain to sprocket to pan. Whether you need a one-to-one OEM match or a performance upgrade, we deliver fast, reliable assemblies backed by field-proven results.

Share your layout drawing or pitch specifications — and we’ll respond with a matched quote, proposal, and delivery plan within 48 hours.

Let us be your conveyor performance partner.

DPC Roller Table

| Model | Pitch | Outer diameter | Width |

| CMECH-DPC-518 | 250 | 108 | 160 |

| CMECH-DPC-590 | 250 | 140 | 200 |

| CMECH-DPC-630 | 250 | 160 | 220 |