Drag Conveyor Chains

Constromech’s Drag Conveyor Chains are engineered for horizontal and inclined conveying of abrasive, hot, and heavy bulk materials — such as ash, cement, clinker, coal, and minerals — within a sealed and controlled system.

Whether your system requires a Single Strand Chain for compact conveyors or a Double Strand Chain for high-capacity, high-torque applications, we offer fully forged, case-hardened chain solutions built for long service life with minimal wear and zero compromise on performance.

Technical Highlights & Construction Features

| Feature | Technical Detail |

| Chain Profile | Drop-forged single/double strand links with wide shoulders for torque stability |

| Material | Alloy steel with refined microstructure; hardened for abrasive and thermal resistance |

| Heat Treatment | Quenched and tempered; case-hardened to 40–50 HRC for high wear performance |

| Pin System | Precision-ground pins with positive locking and shock-load tolerance |

| Flight Attachment | Welded or bolted scrapers in flat bar, T-head, or U-type configuration |

| Pitch Precision | Tight tolerances reduce misalignment, noise, and premature elongation |

| Breaking Load | Chains proof-tested up to 3.2× rated working load |

Single vs. Double Strand Chain – What’s Right for You?

Single Strand Drag Chains

Ideal for low to medium-load conveyors with tight spatial configurations.

- Compact and economical

- Smooth operation at moderate speeds

- Lighter construction — easier maintenance

- Recommended for ash, gypsum, and limestone systems

Double Strand Drag Chains

Built for extreme-duty performance in wide conveyors or high-capacity systems.

- Doubled link rows for higher load distribution

- Handles large volumes of hot clinker, coal, slag

- Greater torque transmission and scraper width

- Used in clinker coolers, bottom ash, and mining conveyors

Application Advantages

- Suitable for fully enclosed conveying — reduces dust, spillage, and environmental exposure

- Low elongation rate — less downtime for retensioning or adjustment

- Compatible with Constromech and OEM sprockets and shafts

- Available with flight wear pads, high-temp bushings, and abrasion-resistant options

- Scraper designs tailored to material flow behavior and conveyor layout

Why Choose Constromech Drag Chains?

Custom-Engineered Options

- Flight design, pitch size, and strand type tailored to your application

- Choose from T-head, U-type, or flat bar scrapers (bolt-on or welded)

System Compatibility

- Ready-to-fit with all standard drag conveyor setups

- Retrofit options available with identical pitch and fitment specs

Complete Assembly Solutions

- Full kit with chains, flights, shafts, and sprockets

- Pre-assembled packages ensure fast installation with minimal shutdown

In-House Quality Assurance

- Proof-loading, NDT, and hardness tests performed on every lot

- Certified QA documents and traceability codes included

Fast Delivery & Engineering Support

- Standard models available with short lead times

- Application support: layout review, flight spacing, wear analysis

Industries Served

✅ Cement & Clinker Conveyors

✅ Power Plant Ash Handling

✅ Steel Plant Slag & Dust Conveying

✅ Gypsum, Lime, and Mineral Processing

✅ Aggregate & Quarry Belt Replacements

Your Chain, Your Load, Our Engineering

Constromech drag chains are built to outperform. Whether you’re designing a new system or upgrading a legacy line, we deliver engineered drag chain systems designed to withstand heat, wear, and heavy-duty operation — with full retrofit and lifecycle support.

Send us your layout or specs to get a custom match.

Let’s keep your process moving.

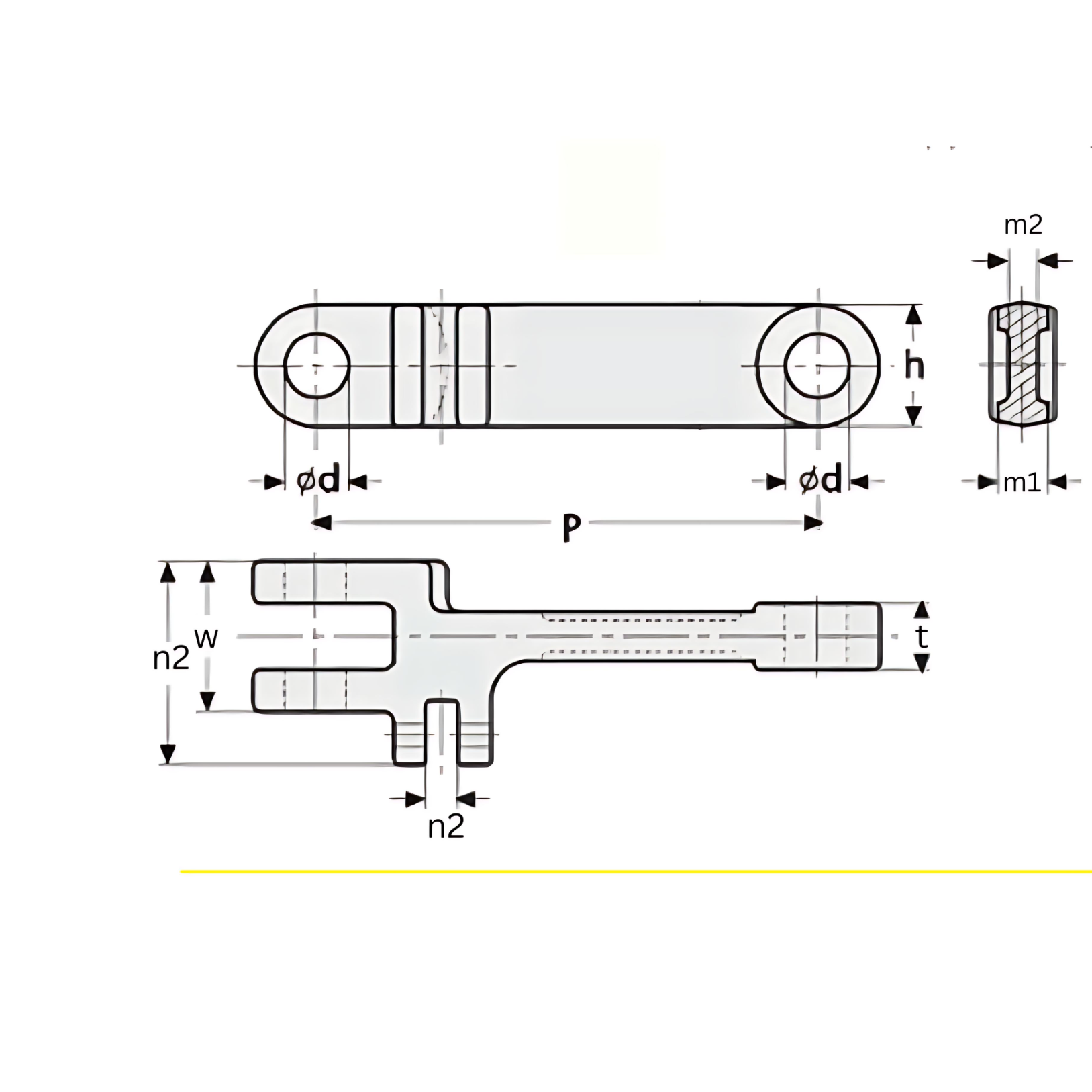

Single strand Drag Chain (Table)

| Pitch (p mm) | Height(h) (mm) | Eye Thickness (t) (mm) | Width (w) (mm) | Hole Diameter (mm) | Web Thickness (m1) (mm) | Web Thickness (m2) (mm) |

| 101.6 | 36 | 12 | 30 | 14 | 8 | 6 |

| 142 | 50 | 19 | 42 | 25 | 13 | 9 |

| 142 | 50 | 25 | 54 | 25 | 16 | 12 |

| 142 | 50 | 29 | 62 | 25 | 16 | 12 |

| 160 | 50 | 25 | 54 | 25 | 16 | 12 |

| 175 | 60 | 30 | 72/62 | 30 | 20 | 14 |

| 200 | 60 | 30 | 70 | 30 | 20 | 14 |

| 250 | 70 | 30 | 70 | 35 | 20 | 14 |

| 360 | 75 | 30 | 70 | 32 | 20 | 14 |

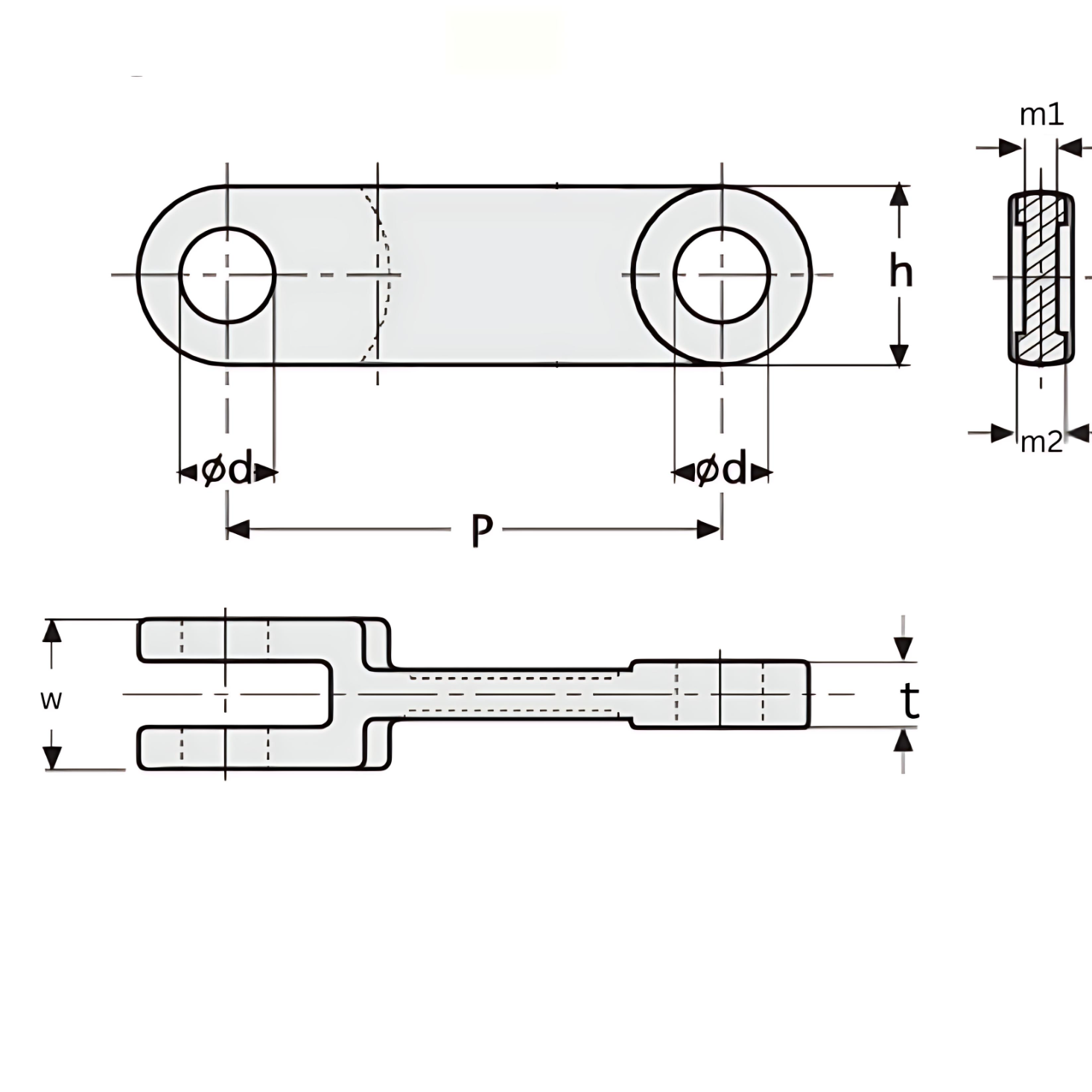

Double strand Drag Chain (Table)

| Pitch(p) (mm) | Height (h) (mm) | Thickness (t) (mm) | Width (w) (mm) | Hole Dia (mm) | Web Thickness (mm) (m1) | Web Thickness (mm)(m2) | Overall Width (mm) (n1) | Side Slot Width) (mm) (n2) |

| 142 | 50 | 19 | 42 | 25 | 13 | 9 | 70 | 13 |

| 142 | 50 | 29 | 62 | 25 | 16 | 12 | 82 | 13 |

| 175 | 60 | 30 | 72/62 | 30 | 20 | 14 | 98 | 16 |

| 200 | 50 | 25 | 60 | 25 | 20 | 14 | 82 | 13 |

| 200 | 60 | 30 | 70 | 30 | 20 | 14 | 100 | 16 |

| 250 | 60 | 30 | 70 | 30 | 20 | 14 | 100 | 16 |